- Home

- Companies

- ARUN Technology Limited

- Products

- ARUN Technology - Model ARTUS 8 (OES) - ...

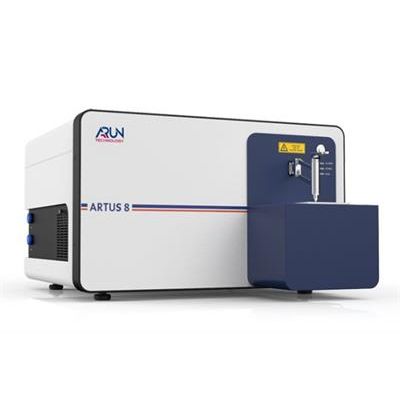

ARUN Technology - Model ARTUS 8 (OES) -CMOS OES Desktop Spectrometer

The ARTUS 8 is a high-performance optical emission spectrometer designed to deliver precise, fast, and accurate analyses, crucial for achieving the perfect melt in metallurgical applications. It excels in providing comprehensive analytical programs for a variety of materials, including cast irons, steels with carbon and nitrogen, as well as all necessary alloying elements in trace amounts. This spectrometer utilizes a flexible and versatile CMOS design, challenging traditional photomultiplier systems which are considered benchmarks in high-end OES technology. The ARTUS 8's dual optical system extends its detection capabilities far into the UV emission spectrum, covering elements like phosphorus, sodium, and lithium, while offering bespoke calibrations tailored for diverse base materials and alloy types. Equipped with cutting-edge CMOS detector technology, the ARTUS 8 ensures high-resolution spectral detection, setting a standard in the field of optical emission spectrometry.

The ARTUS 8 fulfils the requirement of proving fast, precise and accurate analyses for the perfect melt. It is one of the most powerful and reliable spectrometers, offering a complete range of analytical programs, including cast irons, steels with carbon and nitrogen, and all alloying elements and their traces needed for treatment.

It offers all the advantages of a flexible and versatile CMOS spectrometer. It even challenges some applications with classical photomultiplier systems, which are still the benchmark in high-end OES.

ARTUS 8 Standard

- UV-VIS-NIR

- Fe, Ni, Co, Cu, Al, Mg, Zn, Sn, Pb, Ti

- All alloying elements and major traces

- Digital source for high precision

- ARUN factory calibration

- Gas consumption: Low flows, no optic flush, lower grade

- Light path - direct

ARTUS 8 Visible

- VIS

- Al, Mg, Zn, Sn, Pb

- All alloying elements and major traces

- Digital source for high precision

- ARUN factory calibration

- Gas consumption: Low flows, no optic flush, lower grade

ARTUS 8 Ultimate

- VUV-UV-VIS-NIR

- Fe, Ni, Co, Cu, Al Mg, Zn, Sn, Pb, Ti

- All alloying elements and major traces

- Digital source for high precision

- ARUN factory calibration

- Gas consumption: Low flows, no optic flush, lower grade

- Light path - direct

- Optical System :Paschen – Runge

- Wavelength Range :

- 146-680nm (Ultimate)

- 174-680nm (Standard) 70-520nm

- 212-680nm (Visible)

- Power Supply :Line input 90 or 260 Volts AC 50-60 Hz

- EMC :IEC61000-4-2, IEC61000-4-4, IEC61000-4-5

- Working Temperature :10° to 35° C

- Operating Humidity :20-80%

- Argon Purity :99.998% or 99.999% purity

- Argon Flow :When burning – 3L per minute, Standby 0.1L per minute

- Dimensions :721 x 440 x 770mm

- Weight :80kg

- Maximum Excitation Power :400VA

- Optical Source Type :50VA

- Discharge Frequency :400Hz maximum

- Discharge Current :150A maximum

- Spark Stand Aperture :12mm

The ARTUS 8 supports all metal types with the analyses of all their elements, in higher concentrations as well as the relevant traces. The range of factory calibrations is comprehensive with a wide choice of analytical programs for all applications and their alloys that include:

- Iron & steel

- Cast iron

- Aluminium

- Copper

- Magnesium

- Nickel

- Lead

- Tin

- Cobalt

- Titanium

Here are some of the ARTUS 8’s main features:

- Compact bench-top model

- 3-side open spark stand with XY sample clamp

- High-resolution, full-spectrum optical systems

- No vacuum pump, nor argon purge in optics

- Holographic diffraction grating

- High-resolution CMOS detectors

- Digital spark source

- Ethernet connectivity

-

Dual optical system design means the capability to detect elements far into the UV emission range such a P, Na, and Li.

-

Bespoke calibrations for a range of bases and alloy types.

-

The lowest detection limits to detect even trace elements down to the smallest scales.

-

Cutting edge CMOS detector technology enables high resolution spectrum detection.