- Home

- Companies

- TPI - Tecno Project Industriale

- Products

- CO2-Recovery Plant from Dry Ice ...

CO2-Recovery Plant from Dry Ice Production

Increase your productivity and reduce your Dry Ice Production costs by recovering the normally lost CO2 Gas when producing Dry Ice installing one of our latest CO2-Gas-Recovery-Plant. Design will significantly reduce your liquid CO2 consumption and your production costs

TPI’s engineering offers you:

- CO2-Recovery Plants for any type of dry ice unit

- Improves an over-all conversion ratio up to 95%

- Engineered design to minimize factory space used

- All built on a modular skid

- No foundations needed, no alterations to factory floor

How TPI’ system works

Dry ice is produced by suddenly expanding pressurized liquid CO2 under atmospheric pressure. The general conversion ratio will be approx. 40 to 45% of dry ice. In simple words: out of 100kg liquid CO2 only 40-45kg will be dry ice and the rest is normally lost as CO2 gas to the atmosphere.

A TPI CO2-Gas Recovery Plant will be directly connected to the CO2-Gas Exit of the dry ice machine. The CO2 gas will be fed into the balloon above the recovery plant which will act as a buffer for the CO2-Gas Compressor. This dry running compressor will compress the CO2-Gas up to 14-20 bars. At the next stage this compressed gas will be liquefied using a TPI designed liquefaction module. Once the CO2-Gas has been liquefied, it will be fed automatically to the existing CO2-Storage Tank for reuse.

TPI CO2-Gas Recovery Plants are designed for simple, automatic operation all controlled by using a central touch screen to monitor and control its operation.

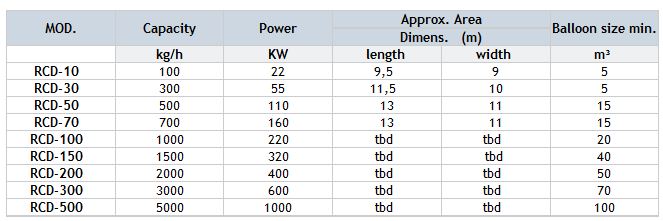

Also small units are available