- Home

- Companies

- Whirlston Machinery

- Products

- Whirlston - Model 4T/H - HM800 - ...

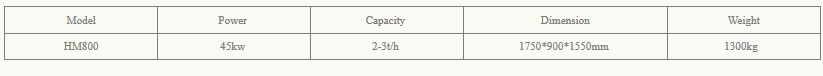

Whirlston - Model 4T/H - HM800 -Coconut Shell Pellet Plant

Literally, pelletized fuel is produced by a wood pelleting machine from either agricultural wastes or forestry residues. However, in order to accomplish the manufacturing safely and successfully, just one machine is not always enough, which is why pellet production line is introduced. For some raw materials, debarking, chipping, crushing, drying, pelletizing, cooling and packing should all be taken into consideration, while for coconut shell pellet line, the first two can be saved because of feedstock properties.

Coconut Shell Pelletinng Process and Main Equipment

Crushing

As the Gist step of 4t`h coconut shell pellet line, crashing means to grind large raw materials into smaller particles or powder. When coconut shells are sent into crushing chamber, the hammers which are rotating speedily under the driving force of rotor will beat them hard. After enough impact and friction, they111 be squeezed out through the screen with a much smaller diameter, less than 5mm.

Features of wood hammer crusher:

- Wider}`applicable raw materials: Various kinds of raw materials can be processed by wood hammer crusher, such as corncob, crop straw, fruit shells, dry grass, wood sawdust and furniture shaving.

- Automatically feeding: The feeding device of wood hammer crusher is able to control and adjust the feedstock amount automatically and reasonably.

- Changeable size: In order to realize both fine and coarse grinding, the size of wood hammer crasher is designed to be adjustable through ^hawging the gap between hammers and screens.