Ionitech - Cold-Wall Plasma Nitriding and Nitrocarburising Equipment

The heating of the parts, in a Cold-Wall plasma nitriding installation, is carried out only by pulsed plasma created in the vacuum chamber. This type of plasma nitriding equipment is especially suitable for nitriding similar in shape and size batches of parts. The main advantages of this type of equipment are:

- Lower cost of the equipment

- Easy maintenance

- Lower consumption of electrical energy

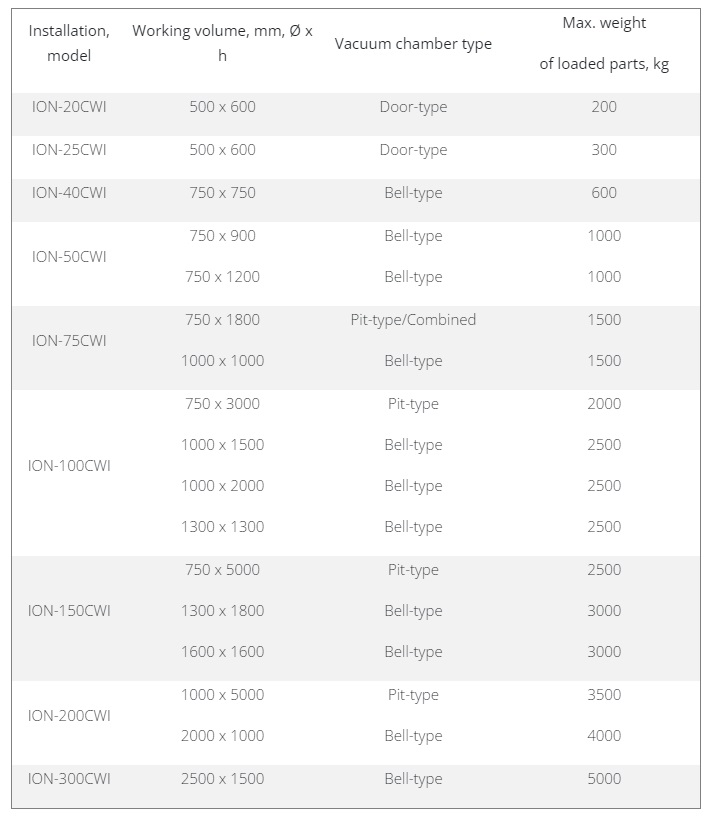

The Cold-Wall vacuum chambers’ type could be:

- Door-type chambers

- Bell-type chambers

- Pit-type chambers

- Combined chambers loaded from the bottom and from the top

The vacuum chambers have double walls, with cooling water circulating in between. In order to decrease the heat exchange between the treated parts and the chamber walls. Two stainless steel shields, separated by thermo-insulating wadding, are installed on the inside surface of the walls and the bottom.

In the door-type chambers and bell-type chambers, the parts are loaded on a metal plate. In the pit-type chambers the parts are attached to special devices to hang. And for the combined-type chambers, the parts could be loaded on a working plate or attached to devices to hang. The metal plate and the special devices for attachment lie on support insulators and are connected to the cathode of the plasma generator. The process of plasma nitriding could be viewed through a sight glass. The temperature during the process is measured directly in the parts using one or two thermocouples K-type.

The plasma generator and its defense mechanism - a power transformer, a three phase thyristor rectifier, a power choke, a power IGBT switch and a number of circuit breakers, filters and contactors, assembled for different supply voltages and mains frequencies. They are mounted in metal cabinet IP 54 that is cooled with an air conditioning.

The gas vacuum system evacuates the chambers and fills them with treatment gases. It includes a vacuum pump, electro-pneumatic and electromagnetic valves, reducing valves with filters and manometers, mass flow controllers, gas mixer, manual valves, two absolute pressure gauges and vacuum connections.

The pressure gauges are mounted on the chambers bodies. The rest of the components are placed in a ventilated metal enclosure IP54. The process is carried out with a mixture of hydrogen and nitrogen. Propane or natural gas are used for nitrocarburising. After the end of the treatment, the chambers can be filled with argon for accelerated cooling. Pressed air is used for the operation of the electro-pneumatic valves.

- • Pressure in the working chamber

- Temperature of the processed parts

- Heat rate

- Ratio and consumption of working gases

- Process time length

- Pulsed Plasma Current

- Frequency of pulses

- Duty-cycle of pulses

- Temperature of cooling water

- Visualization of the technological process parameters

- Review and editing of technological programs, even while the installation is working

- Archive of the technological processes

- Remote access to the archive

- Visualization of the installation alarms

- Alarm notification through e-mail and sms

- Possibility to send process data to Ionitech as attached zip-file through email.

- Input voltage: 3x400V( 480V ) +10%/-15%, 50Hz ( 60 Hz )

- All installation models could be equipped with two chambers working separately - learn more about Ionitech`s Double-Chamber System for no loss in technological time

- Working gases: ammonia, nitrogen, hydrogen, propane, methane

- Cooling gases: nitrogen, argon

- Working pressure: 1 - 8 mbar

- Time for manufacturing 4 - 6 months (depending on the model).

Typical feature of plasma nitriding is the active participation of the treated parts in the glow discharge - the parts act as a cathode, while the chamber acts as an anode. There are many advantages of this method over conventional gas nitriding:

Cost effectiveness- 3 to 10 times reduced duration of treatment;

- 50% - 100 % less energy consumption;

- 50 to 100 times less working gas consumption;

- Distortion - none or negligible distortions, because ion nitriding is performed at lower temperature and under vacuum;

- Higher surface, case and core hardness;

- Excellent wear resistance - the ion nitriding process produces a compound zone which is dense, nonporous, very hard, not brittle, and has a low coefficient of friction;

- Reproducible results and better control - the technological process of ion nitriding is fully automated and computer controlled. The parts are heated by the ion bombardment on their surface and therefore the parts are heated uniformly;

- Surface finish - due to minimum deformations no additional mechanical treatments are necessary;

- Necessity of predepassivation of stainless steel is eliminated;

- Masking - surfaces which require masking are easily masked with reusable mechanical masking devices or special paint for masking - 100 % effective;

- Excellent hygiene and working conditions - the process is not toxic and corresponds to all modern requirements for environmental control.