- Home

- Companies

- REDWAVE - Competence Center of ...

- Products

- REDWAVE - Model CX - Colour Sorting ...

REDWAVE - Model CX -Colour Sorting Machine for Colour Recognition

The new generation of intelligent glass sorting for sorting colours and removing contaminants.

REDWAVE CX

- for coarse grain

- for sorting colours and removing impurities

REDWAVE CXF

- for fine grain

- for sorting colours and removing impurities

REDWAVE CXP

- for removing fine plastics from 3 mm as a clean-up

Up to now dark and thick glass pieces could not be distinguished from CSP due to low transmission value and were ejected along with the CSP reject stream. The sorting of dark glass will significantly reduce the amount of glass loss and increase the productivity rate of the plant.

can now be recognised in a better way. Productivity and yield increase.

CSP rejects stream (ceramics, stones, porcelain) – waste flows are reduced, and disposal costs are decreased.

REDWAVE CX – the future-oriented, new camera technology combined with an optimised light source enables the detection of the most difficult materials.

- Productivity Rate: The loss of glass in facilities will be substantially reduced, and the recovery rate will be increased. This leads to an increase in the productivity rates of the sorting plants.

- Upgrade: A retrofit kit is available to users of REDWAVE CX and REDWAVE CXF sorting machines to upgrade them cost effectively and to include the improved technology.

- Glass Recovery from CSP Stockpiles: Development of an independent post-stage for the recovery of dark glass pieces from the CSP waste of existing plants.

Camera and Light Source Technology

Camera and Light Source

- Developed 100% by REDWAVE

- Specially developed for better sorting performance in dark glass

- High availability of spare parts and low stocks on site and integration of REDWAVE mate

- Own REDWAVE software developed for the best sorting results

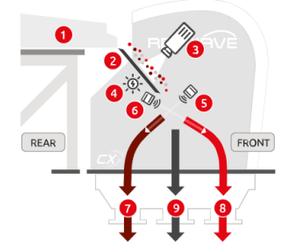

3-Way Sorting

Sorting

- Due to same distance to the recognition of both ejects

- Same performance for both ejects

- No air turbulence influences

- No calculation uncertainties

- 3-way sorting allows efficient plant layouts with fewer machines and therefore less costs

Modules for Your Success

One Sorter is Made of Modules With 500mm or 750mm

- Each module can be set to its own sorting task

- Different grain sizes or even different colours can thus be efficiently sorted in one machine

- Lower spare parts inventory and lower costs

Maintenance Made Easy

Easy to Maintain

- Sophisticated pivoting mechanisms

- Lightweight spare parts

- Easily exchangeable parts

Sensor Fusion

Additonal Sensors for Your Individual Needs

- Additional metal sensor for removing metals

- Additional NIR sensor for removing remaining plastics >3 mm

- Any additional sensors can be upgraded at a later date

REDWAVE CXFP

Reduction of Plastics in End Product

- For sorting the smallest plastic particles >3mm

- Either used directly in the main stage or at the final sorting stage

- Vibratory feeder

- Material slide

- Camera

- Light source

- Valves and nozzles at the frontside

- Valves and nozzles at the rearside

- Chute for eject from front to rear

- Chute for eject from rear to front

- Chute for passing material

The unique 3-way design enables equally high efficiency for both the first and the second ejection. With one ejection on the front and one on the back, the distance between the material scan and the ejection is the same for both sorts. This concept, in combination with the improved, independently developed camera and lighting technology as well as the associated sorting software, enables an unprecedented high detection rate. The powerful valve and nozzle arrangement allow for a compact sorting system with fewer sorting steps.