- Home

- Companies

- Pure Aqua, Inc.

- Products

- Pure Aqua - Model RO-200 - Commercial ...

Pure Aqua - Model RO-200 -Commercial Reverse Osmosis RO Systems

Pure Aqua’s commercial reverse osmosis system “RO-200 series” is a compact and energy-efficient commercial RO unit, designed ideally for tap, brackish and drinking water treatment applications. Our small commercial reverse osmosis equipment is capable of reaching incredibly high recovery rates. As a global supplier, we offer a full line of pre-engineered and custom reverse osmosis systems for commercial use, ranging from 600 to 18,000 GPD. These commercial RO systems produce high-quality water at a very low cost, all of which are engineered using the most advanced technology for accurate and customized solutions.

A commercial ro system will take care of removing unwanted dissolved solids from your tap, brackish or well water through the utilization of highly efficient reverse osmosis membranes. Less wastewater, low energy consumption, high flow rates and contaminant rejection at competitive prices makes our commercial RO system the most valuable in the market. These systems incorporate dependable components and an extremely sturdy construction, along with highly desirable features from years of experiences of producing high quality commercial reverse osmosis purifiers.

Additional perks provided by our commercial RO water system include:

- Compact, Heavy Duty, Powder Coated Carbon Steel Frame

- Membranes from most reputable brands

- Long-lasting performance

- Tried and tested (trouble-free operation)

- Minimal membrane fouling

- Cost-effective

- Enhanced energy efficiency

- Reduction of scaling deposits

- Fresher, clearer improved tasting water

Skid mounted commercial reverse osmosis purifiers are tasked with purifying water from water sources such as lakes, rivers and wells. A commercial RO system utilizes a high pressure pump that pressurizes brackish or saline water against the surface of a semi-permeable membrane containing small pores. Water molecules are only permitted to flow through the small pores while blocking impurities such as salt, particles, minerals, and other organics from passing through. These small pores have a strong capability of rejecting bacteria and disease-causing pathogens. At the end of this process, clean, purified water emerges on the lower-pressured side while salts, minerals, and other organics are sent into the brine stream then into a drain.

Our commercial reverse osmosis units are manufactured to be with user-friendly, environmental friendly, long-term reliability, and robust construction in mind.

A commercial RO system can be customized based on individual design needs to include chemical dosing, cleaning skids, antiscalant, filters and more. Our commercial reverse osmosis machine can accommodate between 600 to 18,000 GPD, with feed water TDS of 1,000 to 5,000 ppm. These features have the capability of removing hardness, chlorine, odors, color, iron, and sulfur. Economical and efficient, RO-200 commercial reverse osmosis machines acquire the latest in reverse osmosis technology to remove dissolved salts, particles, organics, minerals, tannins and other contaminants from the water with a molecular weight greater than 150-250 Dalton. At Pure Aqua, we use the most efficient, energy saving, high rejection membranes made by Dow Filmtec, Hydranautics, Toray.

The following considerations should be made when choosing the right water treatment system:

- Flow rate (GPD, m3/day, etc.)

- Feed Water TDS.

- Iron

- Manganese

- TSS

- SDI< 3

- Water must be free from oils and grease

- Chlorine must be removed

- Available Voltage, Phase, and Frequency

- Installation Location & Footprint

Visit this page to learn more about who makes the reverse osmosis system

A commercial reverse osmosis machine cost is largely dependent on feed water quality and the required product water quality.

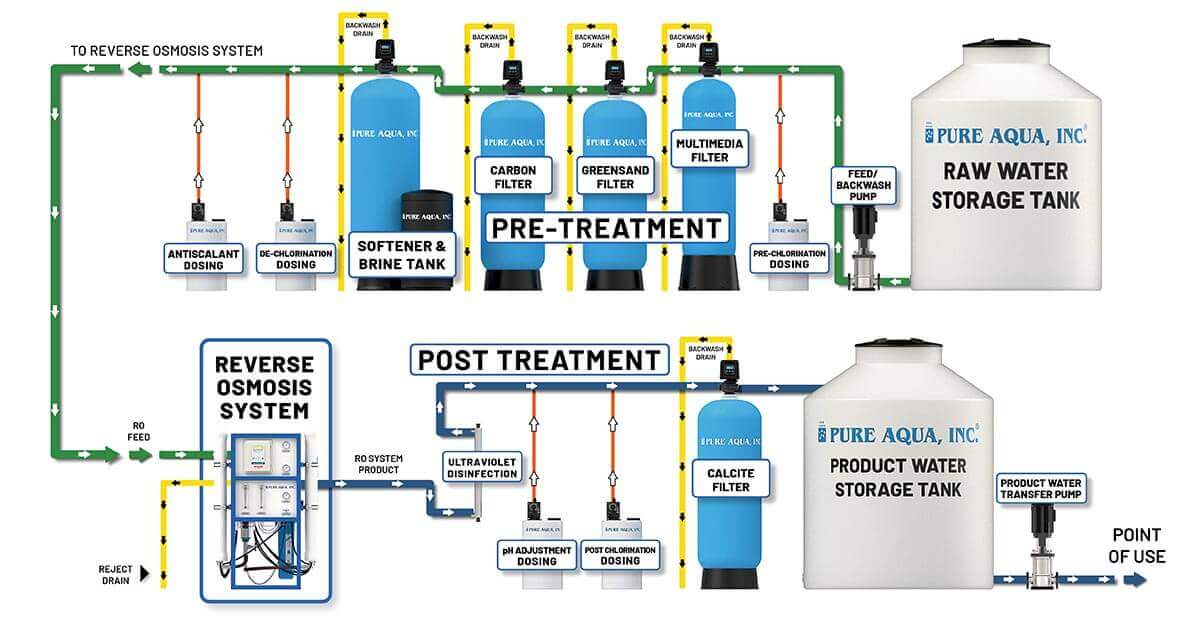

The following list details many of the common pre and post treatment components employed with RO systems.

- Prechlorination dosing

- Media filter

- Carbon filter

- Water softener

- Antiscalant dosing

- NSF components

- Advanced controller

- Advanced instruments

- Iron removal filter

- High TDS application

- Skid mounted system

- Calcite filter

- Blending systems

- Three phase system

- Variable frequency drive VFD

- Max. feed water temperature: 42°C

- Equipment upgrade for TDS up to 5,000 ppm

- Hydrogen Sulfide must be removed

- Max. Silica tolerance: 60 ppm @ 50% recovery

- Feed water TDS: 0-2,000 ppm

- Operating pressure: 150 to 250 psi

- pH tolerance range: 3-11

- Max. Iron content: 0.05 ppm

- Feed water pressure: 20 to 80 psi

- Hardness over 1 GPG requires water softener or antiscalant

- Turbidity should be removed

- Operate at higher TDS by lowering recovery

- 2.5"/4" TFC spiral wound membranes

- Heavy duty high pressure tubing

- Low pressure switch

- Product and reject flow meters

- Electric inlet solenoid valve

- Corrosion resistant high pressure throttling valve

- Pretreatment lockout

- Factory tested

- Powder coated carbon steel frame

- Corrosion resistant high pressure pump

- 220V/1Ph/60Hz power supply

- Pre/post-treatment and pump pressure gauges

- Recycle valve (standard up to 4.5K GPD)

- FRP/SS pressure vessel

- Tagging and identification of instrumentation

- Heavy duty 5 micron cartridge pre-filter

- Automatic flush

- Pre piped skid system

- Blending: feed/product

- Tank float switch

- Recycle flow meter

- Post DI polishers

- 380-415V/3Ph/50Hz power supply

- 220-240V/1Ph/50Hz power supply

- 220V or 460v 3Ph/60Hz power supply

- Water softeners

- UV sterilizers

- Media filters

- pH or ORP meter

- High pressure switch

- Export wood crating

Commercial reverse osmosis plants are built using 4” TFC spiral wound membranes, commercial water pumps and microprocessor based control panels. The ideal application for a commercial RO water filter systems include:

- Electronics/Metal Finishing

- Beverage Production and Bottled Water

- Stormwater Treatment

- Pharmaceutical

- Mining Industry

- Chemical Blending

- Safe Drinking Water

- Rinse Water

- Nitrate Removal from Water

- Plating Operations

- EDI Pre-treatment

- Food and Beverage

- Spot Free Product Rinse

- Cooling Towers

- Laboratory

- Boiler Feed Water

- Ice Manufacturing

- Ion Exchange Pre-treatment