- Home

- Companies

- bioCycle Ltd

- Products

- bioCycle - Commercial Treatment System

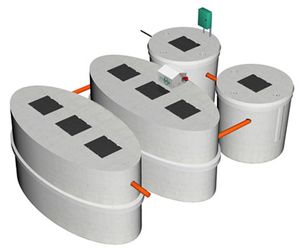

bioCycle - Commercial Treatment System

bioCycle™ specialize in the design, installation and servicing of treatment systems ranging in size up to 1000 P.E. Systems can be designed to meet the most stringent of discharge licenses and can incorporate UV disinfection, denitrification and phosphorous removal processes.

- Highest Treatment Performance

- Reinforced Concrete Tank

- Longest Desludging Intervals 7-10 Years

- Tested & Certified to EN 12566-3

- Agrément Certified

- Multiple Safety Features

- Proven system with over 20 years successful operation

Primary Chamber

bioCycle™ wastewater treatment systems incorporate large primary chambers to allow extended sludge retention. Sludge when stored for greater than 18 months will degrade through anaerobic digestion. The advantage of extended retention in the primary chamber is that the system will require infrequent desludging; also the solid content will be significantly reduced thus reducing the pollutant load entering the secondary treatment stage. Sludge from the clarification stage is returned to the primary chambers for storage.

Aeration Chamber

The bioCycle™ system is a fixed film reactor. Aerobic bacteria breakdown the waste and in the process consume oxygen. As a result, oxygen is supplied at this stage via air blowers. Media with a high specific surface area is contained in the secondary treatment chambers, providing the optimum environment for bacterial flocs to form. Flow control baffle walls allow anoxic zones to be created at the end of the chambers, resulting in denitrification and phosphorus removal process to occur.

Clarification Chamber

The clarification chamber is designed to provide quiescent conditions allowing any bacterial flocs remaining in the effluent to settle out. Sludge from the clarification stage is returned back to the primary and secondary treatment chambers.

Pump Chamber

The large pump chamber allows the treated effluent to be stored before it is pumped to the polishing filter or surface irrigation system. The pump is operated intermittently to ensure low energy usage.

Polishing filter (percolation area)

bioCycle™ provide a range of designs of polishing filters which are installed by our experienced crews. The treated effluent is pumped to the topsoil layer where it is allowed to percolate through the filter media (soil or sand) where further reductions in nutrients and bacterial contaminants will occur.