Jiangye - Complete Equipment for Recovery Spent Printed Circ

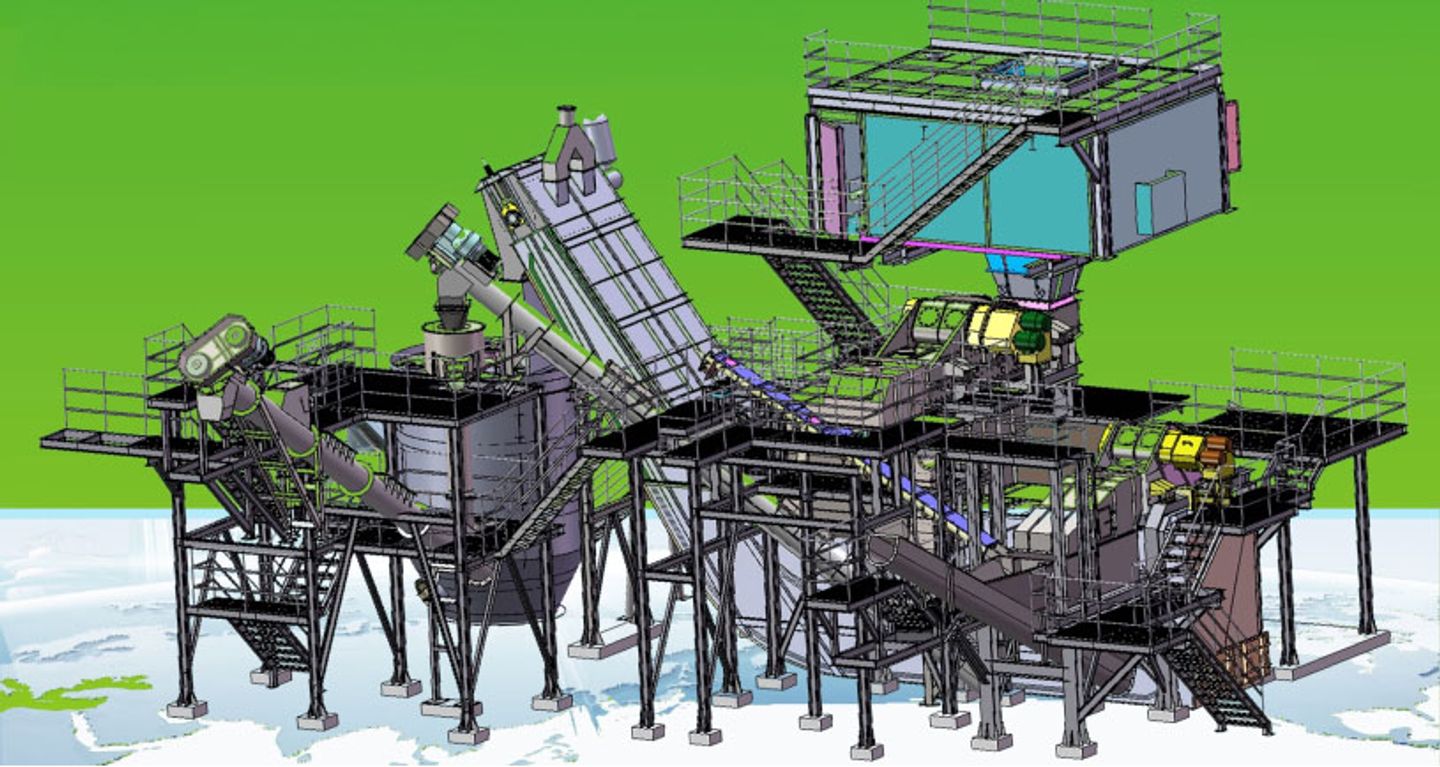

Spent ithium ion crushing ansorting complete equipmentand technology`, has established an industrial demonstration line with an annual processing capacity of 5000t/a. Considering the large process of lithium battery recycling, the goal is to regenerate resources with maximize benefits.

Adopting `charged crushing-elec-lrolyte pretreatmenthigh temperature pyrolysis-full-component phys-ical sorting process`, effectively solves the problem of long discharge cycle of salt water, electrolyte water pollution, easy shortcircuit discharge during crushing process, and failure of positive and negative electrode powderpeeling Thorough, high content of copper scraps and aluminum scraps in polar powder, fluoride pollution and other technical problems in a series of industries.

Recycling the diaphragm, pile head shell, copper foil, aluminum foil, and positive and negative electrode powders in waste lithiumion batteries is safe, environmentally friendly and efficient to achieve resource recycling. The recovery rate of polar powder is > 96%, and the grade is >98%. Through online oxygen content + temperature detection + video monitoring, PLC and centralized interlocking control of position machine.