Henan Greatwall Machinery Co., Ltd.

- Home

- Companies

- Henan Greatwall Machinery Co., Ltd.

- Products

- Greatwall - Model PYCC Series - ...

Greatwall - Model PYCC Series -Compound Cone Crusher

The PYCC series compound cone crusher for sale has a more reasonable and complete structure and a more advanced technical parameter, which has excellent performance in manufacturing, installation, use, and maintenance. Cone crusher is used for crushing various ores and rocks with medium and above medium hardness.

Most popular related searches

compound cone crusher

cone crusher

non-ferrous metal

water conservation industry

cement industry

water conservation

tertiary crusher

hydraulic cylinder

crushing equipment

construction site water

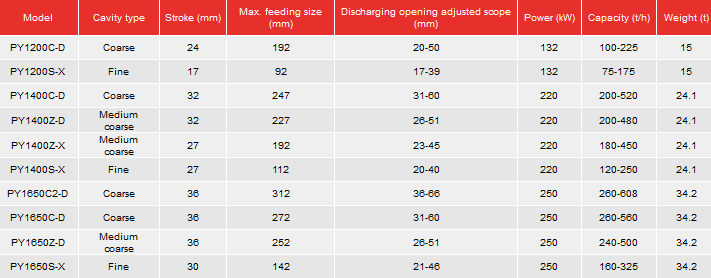

- Processing Capacity: 12-1000TPH

- Max. Feeding Size:92-312mm

- Application Fields: Mining, metallurgy, construction, highway, railroad, water conservancy, cement industry, and ore processing, etc.

- Applied Materials: Granite, river stones, boulders, pebbles, diabase ,basalt, black stone, andesite, feldspar, quartz, limestone, dolomite, calcite, talc, barite, kaolin, iron ore, copper ore, manganese ore and gold ore etc.

- Customized Service:Production flowchart, formal quotation offer, installation instruction, wearing parts service will be provided as per detailed discussion with customers. Small, medium and large models can be customized, to meet customers’ demands.

The compound cone crusher is a comprehensive cone crusher with a spring and hydraulic cylinder in. It is suitable for crushing various ores and rocks with medium and above medium hardness, such as iron ore, cobblestone, non-ferrous metal ore, granite, basalt, limestone, quartz, and sandstone. The optimized and improved PYCC series compound cone crusher has a more reasonable and complete structure and a more advanced technical parameter, which has an excellent performance in manufacturing, installation, use, and maintenance.

What Is Compound Cone Crusher Used for?

It is widely used in mining, metallurgy, construction, highway, railroad, water conservancy, cement industry, ore processing industry, etc.

And it is usually used as a secondary or tertiary crusher, for materials including granite, river stones, boulders, pebbles, diabase, basalt, black stone, andesite, feldspar, quartz, limestone, dolomite, calcite, talc, barite, kaolin, iron ore, copper ore, manganese ore, and gold ore, etc.

- With a large crushing ratio, big main shaft eccentricity, wide feeding opening, and small discharging opening, the capacity becomes maximized.

- It only takes two hours to change the mantle or concave, reducing the downtime

- Anti-dust structure of the compound cone crusher is unique, the sealing effect is reliable, and extended the replacement period of lubrication oil, the service life of bearing, bearing bush, gear, etc.

- The distance between the mantle and concave become larger in every stroke, it not only can be fed in materials but also produce a big discharging product, and the material passing through the cavity speed becomes fast.

- Daily operation and maintenance cost is low.

- It has hydraulic adjusting, locking, and clearing system, improving the operability and reducing power consumption.