- Home

- Companies

- Zhengzhou Taizy Machinery Co. LTD

- Products

- Taizy - Continuous Chain Plate Tunnel ...

Taizy - Continuous Chain Plate Tunnel Oven with Cooling Part

The continuous chain plate oven is a new type of multifunctional roasting (drying) machine for peanuts, grains, and nuts. It can be used in the peanut butter processing plant. Its advantage is a high degree of automation and automatic temperature adjustment. The heat source can be electric heating, gas heating, and other heating methods. The circulating fan is used to exchange heat to achieve strong airflow baking, improve baking efficiency, and improve baking quality. The rear section of the equipment is equipped with a cooling zone to realize the integrated production of roasting and cooling, and the equipment has a compact structure.

This continuous tunnel oven includes an elevator to hoist raw materials, a feeding hopper, a roasting part and a cooling part, an outlet. In the roasting part, for the work of the heating source, there will be heat circulation inside the tunnel oven. And the large-scale baking oven could apply electricity or gas as heating resources. With a chain plate conveyor belt, peanuts could be roasted fully and have more good taste in the machine. As for the cooling process, the oven reduces the temperature of materials with a fan machine to produce natural wind. So the final discharged peanuts could be ground into peanut butter directly.

Different Types of conveyor belt tunnel oven

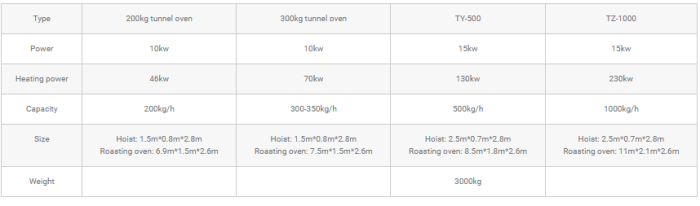

For different requirements of customers, we could provide continuous roasting ovens of different outputs. There are 200kg, 300kg, 500kg, and 1000kg conveyor belt baking ovens.