Most popular related searches

material flow monitoring

flow detection

pipe clamp

solids flow

flow monitoring

pipe detection

integrity monitoring

sensor data

flow limiter

cement industry

- Absolutely insensitive against material deposits

- For any line diameter

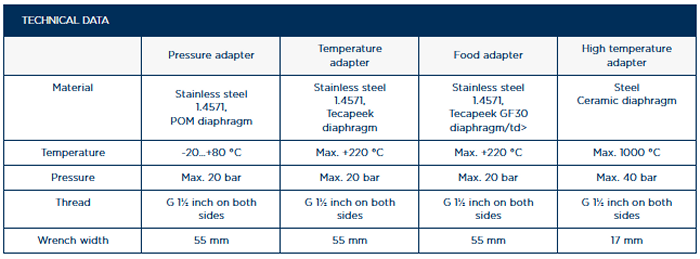

- With adapter, usable up to 220 °C and 20 bar

- With ceramic mounting, usable up to 1,000 °C

- Usable indust ex-zones

- Detection through all non-conductive walls

- Can also be supplied as compact device with integrated electronics

- Detection of material clogging and material standstill

- Steel

- Food

- Biomass

- Cement

- Chemistry

- Coal plant

- Coating

- Incineration

- Minerals

- Wood

- Lime plant

- Energy

- Gypsum

- Power plant

- Foundry

- Material to detect: Dust, powders or granulates

- Working principle: Microwave

- Process pressure: Max. 20 bar

- Process temperature: Up to +1000°C

- Mounting: 1 1/2 ” threat connection

- Type of Conveying: All

- Flow rates: No limit

- Pipe diameter/detection range: Up to 1200 mm

- ATEX rating: Category 3

- Output: Relay, 4…20mA Trend

- Detects solid flows of all types for material movementOperates with no contact, using microwaves in a process in which the material movement is detected by using the Doppler effect

- If container walls, housings or pipelines are not metal, it is possible to measure from the outside

- Can also be used under difficult conditions such as high operating temperatures and pressures as well as dust and gas ex-zones with the help of a process adapter

Sensor Technical Data

- Voltage: 12 V DC powered by transmitter

- Power consumption: Approx. 1.5 W

- Housing: Stainless steel 1.4571

- Protection system: IP 65

- Using in Ex-zones: Outside pipe: Cat. 3 D

- Inside pipe: Cat. 1/3 D

- (only with process adapter)

- Process temperature: -20… +80 °C (standard)

- -20… +220 °C (with process adapter)

- -20…+1000 °C (with ceramic flange)

- Ambient temperature: -20…+60 °C

- Working pressure: Approx. 560 g

- Detection range: 0 – 2 m (dependent on application)

- Required material speed for detection: Min. 0.1 m/s

- Measuring frequency: K-Band 24.125 GHz; ± 100 MHz

- Transmitting power: Max. 5 mW

- Dimension FlowJam S: Housing: L 103 mm / Ø 52 mm

- Thread: L 30 mm / Ø G 1½”

- Dimension FlowJam S Ex: Housing: L 147 mm / Ø 60 mm

- Thread: L 15 mm / Ø G 1½”

- Cable gland: M16 (Ø 5-10 mm)

- Weight FlowJam S: Approx. 560 g

- Weight FlowJam S Ex: Approx. 850 g

Transmitter Technical Data

- Power supply: 24 V DC ± 10 %

- Power consumption: Approx.. 3.5 W

- Relay contact: Max. rated load: 250 V AC

- Max. peak current: 6 A

- Max. rated load 230 V AC: 250 VA

- Max. breaking capacity DC1:

- 3/110/220 V: 3/0.35/0.2 A

- Min. switching load: 500 mW (10 V/5 mA)

- Analog output: 4 … 20 mA

- Fall-delay time: 250 ms…15 s (continuously adjustable)

- Weight: Approx. 172 g

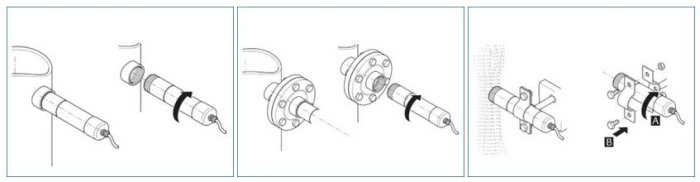

The FlowJam S can be easily installed in the following ways:

- Screwing into a 1 ½-inch-threaded connection

- using a DN 40 flange as well as

- using a pipe clamp or other holding bracket