sera - Controllable Multi-layer Diaphragm Pumps

Field of application: Flow free mediums with aggressive, viscous, radioactive, flammable, odorous or toxic characteristics.

Field of application:

- Flow free mediums with

- aggressive

- viscous

- radioactive

- flammable

- odorous

- or toxic characteristics

Capability characteristics:

- Increased operational safety

- Longer diaphragm lifetimes

- Higher feed pressure

- Leakage-free

- Highest dosing accuracy

- Dry run safety

- High quality materials

- Continuous operation with minimum maintenance

- Long operating life

- Easy to operate

- PROFIBUS-DP interface

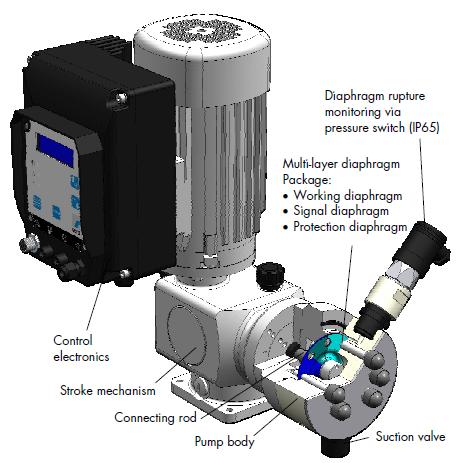

Controllable multi-layer diaphragm pumps generation 4

- Future-orientated pump concept by integral multi-functional control electronics

- High operational safety by multi-layer diaphragm technology

- Checking of the diaphragm by permanent and automatic diaphragm rupture monitoring

- Easy commissioning with "Plug & Dose" standard configuration

- High application security for viscous media due to slow-mode technology

The operating principle of the multi-layer diaphragm pump is the same as that of the common diaphragm pump. The diaphragm is coupled mechanically and oscillating via a connecting rod — this way feeding the dosing medium.

By using the multi-layer diaphragm these pumps can now handle dosing tasks with higher requirements regarding safety. Such demands will be fulfilled by the higher lifetime of the multi-layer diaphragm in comparison to single layer diaphragms and thanks to the integrated diaphragm rupture signalization (manometer as standard plus optional pressure switch).