- Home

- Companies

- MinPlus B.V.

- Products

- MinPlus - Controlled Thermal Conversion ...

MinPlus - Controlled Thermal Conversion (CTC) Process

MinPlus® is produced in the patented “Controlled Thermal Conversion” process (CTC) from the otherwise discarded mineral fraction of paper recycling. The process is CO2 neutral. Small particulate lime and clay minerals are re-used in a wide-pore layered highly reactive mineral mixture with a melting point of more than 1.300 °C. The powdery MinPlus® additive is pneumatically dispersed into the empty drafts of waste incinerators at typical flue-gas temperatures of 800 – 1.100 °C, where it binds HCl, SO2 and HF upstream of the boiler superheater parts, simultaneously preventing the formation of hard deposits and high-temperature melting corrosion of downstream boiler parts.

Dosage rates of typically 1,5 g MinPlus® per Nm3 of flue-gas result in significantly increased availability and increased interval length between planned stops, while simultaneously reducing the amounts of traditionally applied flue-gas cleaning additives like lime, sodium hydroxide, or sodium bicarbonate.

What’s gone is gone – Boiler protection, plant optimization, and reduction of operational cost all done in one step. Application of MinPlus® alleviates the effects of incinerating non-homogeneous hazardous waste fuels by reducing melting points of fly-ash as well as immobilizing HCl, SO2 and HF from the flue-gas in the incineration-zone itself – before harm is done to downstream processes. Formation of deposits is inhibited, corrosion is prevented, and the use of expensive flue-gas controlling additives is reduced. Energy-from-waste plants that apply MinPlus® operate more steady, more efficiently, and at reduced cost.

Up to 3 % increased steam production

Waste incinerators using MinPlus® have shown up to 3 % increased steam production on average between planned stops by maintaining a constant boiler exit temperature.

≥ 1:1 replacement of flue-gas control additives

MinPlus® replaces conventionally applied additives such as:

- Sodium hydroxide

- Sodium bicarbonate

- Lime

100 % throughput between planned stops

Do you have to reduce your throughput at the end of an operating period between stops? MinPlus® allows you to maintain constant full capacity.

MinPlus® adsorbs acidic flue gas constituents as HCl, SO2 and HF already starting at temperatures as high as 1.200 °C. It is therefore applied in the first and/or second draft upstream of super heater boiler parts.

Up to 100 % reduction of explosion cleaning

Seriously reduced effort in explosive boiler cleaning, even for the worst boiler deposits, thanks to the reduction of boiler fouling when applying MinPlus®.

30 % increase in availability

Back to back comparison of similar waste incinerator lines with and without the application of MinPlus® shows a significant increase in on-stream time.

Protection against fouling and corrosion

Amounts as low as 1,5 g of MinPlus® per Nm3 of flue-gas already provide protection against boiler deposits and corrosion, at the usual flue-gas concentrations of HCl and SO2.

Few and mild deposits

Evaporator and super heater surfaces appeared almost free from solid and molten deposits after the application of MinPlus® for 4 months. Remaining deposits were found to be loose, sandy, simple to remove, and easy to transport.

Double service life of superheaters

Application of MinPlus® demonstrated a doubling of the service life of critical superheater parts through the abatement of high-temperature corrosion.

The wall-thickness of super heater tubes showed no decline after more than 11 operational months.

103-fold reduction of leaching

A 103-fold reduction of the eluation of heavy metals, chlorine, and sulphur compounds from boiler ash when applying MinPlus® eases the disposal of incineration residues (ash).

Interested?

If you would like to discuss the application of our mobile demonstration equipment at your site, please contact us at: info@minplus.com

The production of MinPlus® is TÜV certified as CO2 negative when compared to the production of conventional lime based materials. The CO2 comparison for the production of sodium hydroxide or sodium bicarbonate is even more beneficial.

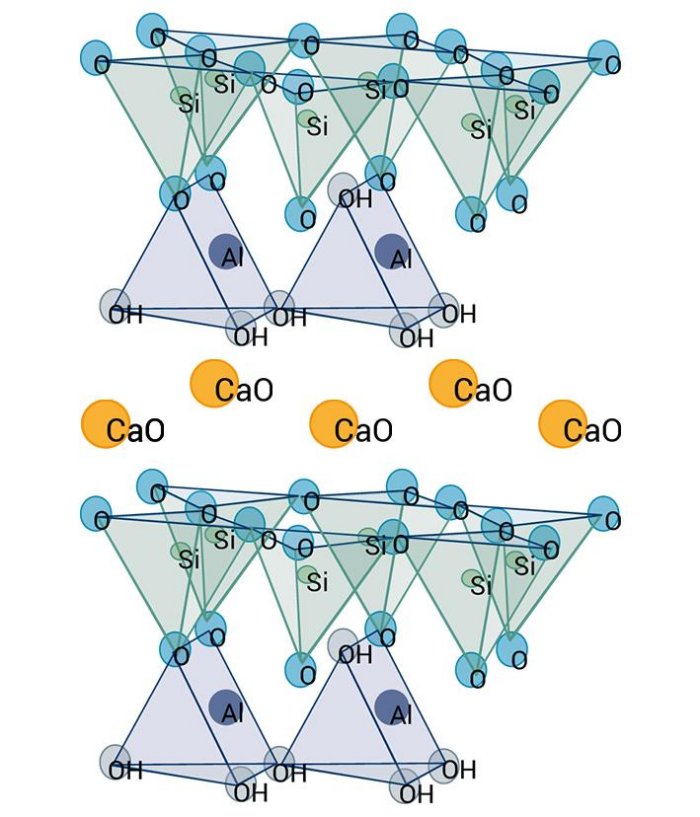

The compound in MinPlus® that immobilizes HCl and SO2 from the flue-gas is calcium oxide (CaO), which is embedded in the wide-pore metakaolin layered-silicate grid on a molecular level. This structure, which is totally different from that of usually applied calcium-based additives, results in a reactive well-accessible microstructure exposing all calcium compounds to the flue-gas.

Calcium carbonate that is also embedded in the core structure is furthermore calcined in the first drafts at a rate that is more than 10 times faster than that of normal carbonates which do not show appreciable calcination under these conditions, resulting in an additional supply of ultra-reactive CaO. The high melting point of the metakaolin furthermore reduces boiler deposit formation through increasing the melting point of the fly ash.