- Home

- Companies

- VAF Filtration Systems - a brand by ...

- Products

- VAF - Cooling Tower Filter Systems

VAF - Cooling Tower Filter Systems

Virtually every industrial or commercial facility has a cooling tower. Furthermore, statistics point to as much as 5% of municipal water is used each year in cooling tower makeup.

Cooling Tower Filtration Advantages:

- Maintains heat transfer efficiencies

- Increases system life

- Reduces treatment chemical costs

- Enhances effectiveness of water treatment program

- Reduces maintenance by minimizing the need for manual cleaning

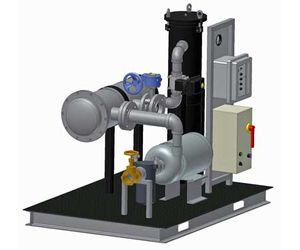

VAF Filters Offer State-of-the-Art Automatic Self-Cleaning Filtration

The patented BHD (Bi-directional Hydrodynamic Drive) improves screen cleaning efficiencies resulting in:

- 100% screen cleaning with controlled suction nozzle rotation

- Flush waste is less than 1% of filtrate flow

- 70% fewer moving parts

- Pre-assembled filtration systems to meet any flow demand

- Filtration 10-1500 micron

- V-Series filter bodies, models 250-1500, manufactured in 316L stainless steel

- All systems competitively priced

- Qualifies for LEED and Made in America funding

Remove Inorganic and Organic Particulates Including:

- Sand

- Silt

- Scale Particles

- Rust Particles

- Algae

- Chemical Residue

System Cleaning Features:

- Standard flow range from 23 to 341 m3/hr (100 to 1,500 gpm)

- 10 to 15 seconds for each flush

- Flushing initiated at 0.5 bar (7 psi) pressure differential

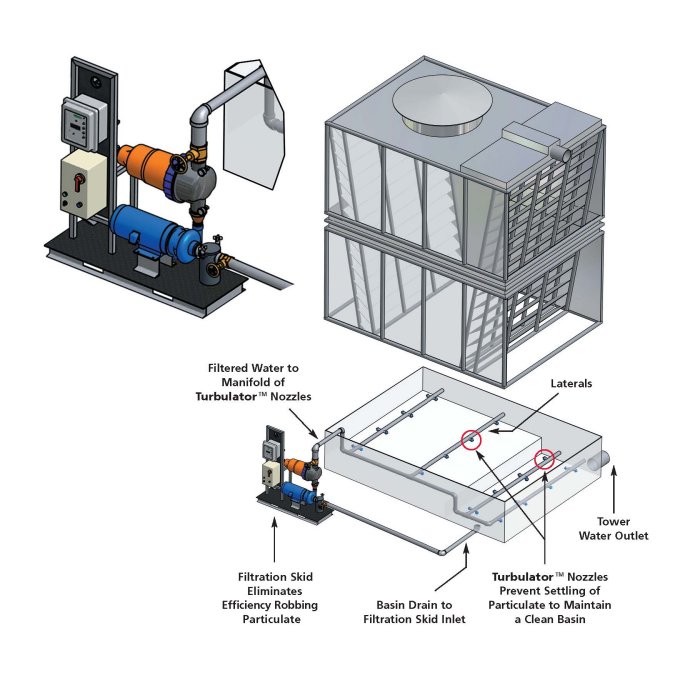

VAF Cooling Tower Basin Agitation System

Keeping the cooling tower basin clean is another important aspect of cooling tower filtration. VAF offers a Cooling Tower Basin Agitation System composed of TurbulatorTM Eductor nozzles that agitate the basin water and keep solids in suspension to be removed by filtration.

The optional 100% Recovery Vessel provides for:

- Zero Cooling Tower Waste

- Zero Loss of Chemicals and reduces makeup water requirements due to the flushing of filters

Stop water and chemical waste! Recover the flush water!