- Home

- Companies

- Amisy Metal Recycling Machinery

- Products

- Amisy - Model 600 - Copper Wire ...

Amisy - Model 600 -Copper Wire Recycling Machine

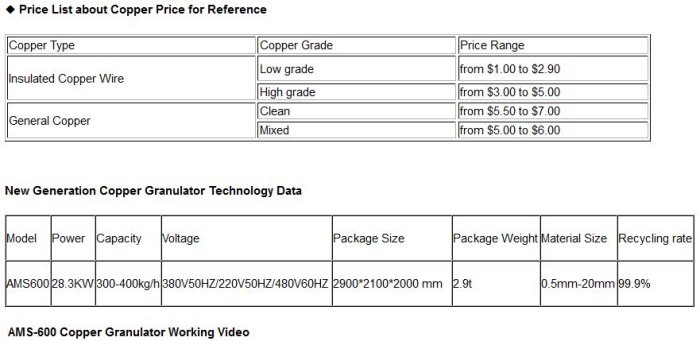

The Introduction of AMS600 Scrap Copper Aluminum Wire Granulator AMS600 Copper Wire Granulator is specialized to process kinds of automotive wire, communication cables and other scrap wires whose diameter is not more than 20mm. Furthermore it can process miscellaneous wires that can not be handled by wire stripping machine. After crushing processing, the copper and the plastic are separated by vibration sieve completely and there is no dust, no secondary pollution in the whole dry type processing. Therefore this model of scrap copper wire granulator has high economic benefit. Application of AMS600 Scrap Copper Wire Granulator 1. AMS600 copper wire granulator is specialized to process kinds of automotive wire, communication cables and other scrap wires whose diameter is not more than 20mm, and even aluminum cable is available. 2. It can process miscellaneous wires that can not be handled by wire stripping machine. 3. It can handle a wider range of material by incorporating a pre-choppe1. Wide application: The material of the waste wires can be telephone wire, household electric wire, automotive wire and cables whose diameter should be within 20 mm.

2. Easy Operation: This type of waste cable recycling machine needs no water during the whole process. What you need to do is only to put the waste wire/cable into the feeding device. Then the copper and plastic will be separated by vibrating separator, and the copper purity can be 99%.

3. Labor-saving: Copper Granulator is an integrally combined machine which needs only 1-2 workers to operate. The machine is of compact structure, less land occupancy and labor-saving.

4. Customized services: We can customize different voltage motors of 220V/380V/480V. We can also customize motor according to your special requirements.

5. Convenient Shipment: All the units are installed on the underbed to form the whole machine which is very easy for transporting. The machine is well adjusted before shipping, so the customer only needs to connect it to the power supply before production.

1. Copper Wire Crushing process

Put waste copper wire/cable into crusher to grind the wire into granular mixture. The crusher blade of high quality would change the wires or cable into particles.

2. Copper Clad Collecting.

After crushing, the mixture of copper and plastic will be blowed to the separating process by a high pressure blower. The crushed granule particle are driven by two vibrating motor. Because of different gravity, the copper clad is easily floating up and collected by the blower.

3. Separating and Copper Granule Collecting Process

The vibrating screen is tilt installed which makes the separating process much easier. Also, during vibrating process, a blower will pull the plastics out from one of the discharging hole. Then the copper granule will be filtered by vibrating screen of 150 mesh.