Corebon AB

- Home

- Companies

- Corebon AB

- Products

- Corebon - Heated Shell Tools for ...

Corebon - Heated Shell Tools for Composite Material Processing

FromCorebon AB

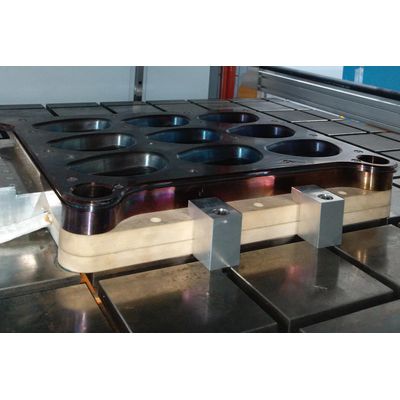

Heated shell tools, also referred to as thin-walled metal tools, are essential in the vacuum forming of composite parts and are adaptable for both autoclave and non-autoclave processes, as well as for compression molding. Corebon has developed a unique method of integrating inductor coils directly onto the back side of these tools, enabling rapid heating with significantly reduced energy consumption compared to conventional systems. These tools are versatile, suitable for processing most thermoset composites and handling high-temperature thermoplastics. Furthermore, Corebon offers customization and retrofitting options, allowing clients to integrate their innovative inductors into existing setups or new tailor-made designs. To meet diverse operational requirements, the tools can be equipped with forced air or water cooling systems. Corebon's solutions are designed to enhance efficiency in composite material processing.Most popular related searches

forced air

molding material

water cooling

cooling system

autoclave

air cooling system

cooling water

cooling water system

Thin-walled metal, also known as shell tools, are used for vacuum forming of composite parts, either in or out of autoclave, or for compression molding. Corebon’s unique method for applying inductor coils directly to the tool’s back side equips them for even faster heating at a fraction of the energy use of other systems.

Our base shell tool configurations are suitable for most common thermoset composites, as well as high-temperature consolidation and processing of thermoplastics. We also offer customized solutions on request.

Corebon inductors can be retrofitted to existing shell tools, or integrated into new customized shell tools. You can also have forced cooling with air or water depending on your needs.

- Mold material: Steel, nickel, kovar, invar, or aluminum

- Temperature range: Up to 250°C or 430°C (active cooling of inductor)

- Heat rate: 1-100 °C/min