- Home

- Companies

- Hunan Yuanheng Technology Co., Ltd.

- Products

- YHCooling - Model YCN-F - Counter Flow ...

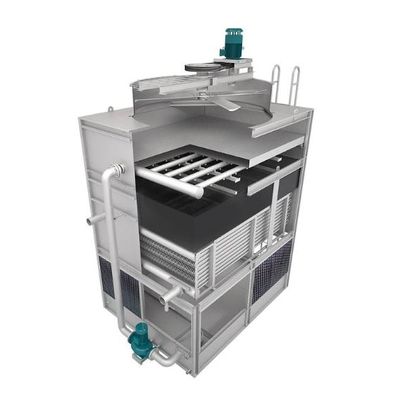

YHCooling - Model YCN-F -Counter Flow Closed Type Cooling Tower

Closed circuit cooling tower is suitable for various kinds of cooling systems with high quality requirements of circulation water, widely used in electric power, chemical, steel, food and many other industrial sectors.

Counter flow closed type cooling tower YCN-F series are suitable for various kinds of cooling systems with high quality requirements of circulation water, widely used in electric power, chemical, steel, food and many other industrial sectors. On the other hand, compared with air cooling heat exchanger, evaporative cooling tower has obvious advantages and makes transfer increases significantly by the tube side of latent heat of water vaporization.

This type of counter flow closed circuit cooling tower YCN-F combines indirect and direct cooling technology. Water are pump energized and circulates up to the water distribution system. Water is evenly distributed through large orifice nozzles as a thin film over the extended fill surface for maximum cooling efficiency. Simultaneously, the fan system moves large volumes of air through the unit in the opposite direction of the falling water. The air and water contact directly across the fill surface, whereupon a small portion of the spray water evaporates; the warm and saturated air is then discharged from the unit, removing heat from the system. The spray water exits the filling section as a cooled fluid where it is collected by the redistribution basin for even soaking of copper coils or stainless-steel coils. The hot process fluid enters the coil through the bottom coil connections. The heat load is rejected to the circulating water that cascades over the coil surface by means of sensible heat transfer.

- Improve production efficiency, softened water circulation, no scaling, no blockage, and no loss;

- Prolong the service life of equipment, secure reliable and stable operation, reduce failure rate, and prevent accidents;

- Full closed circuit, no impurity entering, no medium evaporation, no pollution;

- Improve the plant’s utilization coefficient, no pool; reduce floor area, save space;

- Small space taking, convenient to install, move and arrange, compact structure;

- Convenient operation, stable running, high degree of automation;

- Operation cost savings, a variety of automatically switched models, intelligent control;

- A wide range of uses, medium of no corrosion to the heat exchanger, direct cooling;

- Low operation and maintenance cost.