- Home

- Companies

- Canada Pipeline Accessories

- Products

- CPA - Sonic Nozzles

CPA - Sonic Nozzles

CPA Sonic Nozzles protect gas meters and other pipe equipment from damaging high velocity flows. They provide reliable and repeatable flow-limiting behavior, and can be manufactured to protect all types of positive displacement, turbine, and orifice meters. CPA sonic nozzles are manufactured to the ASME 7M industry standard.

- Suitable for protection of all types of flow meters, probes, strainers, valves, and other equipment.

- Custom manufactured for your exact process conditions.

- No moving parts, no maintenance requirements, and low fouling rate.

- Available in a range of sizes, and materials.

- Excellent reliability and repeatability.

- Nozzles are manufactured to recognized industry standards, such as ASME/ANSI, or with a stepped throat which increases stability at critical conditions

Sonic nozzles work by creating a restriction in the pipeline. This restriction forces the gas velocity to increase at the throat of the nozzle. If the pipe flow rate gets high enough, the velocity at the nozzle throat reaches the local speed of sound. When this occurs, the flow is choked, and the mass flow rate through the nozzle cannot increase any further.

A choked nozzle prevents the gas velocity in the pipe upstream of the nozzle from increasing as well. This condition protects anything installed in front of the nozzle, even if the downstream suction pressure continues to be reduced.

The CPA Sonic Nozzle must therefore be installed downstream of the pipe equipment it is meant to protect. The flow velocity in the pipe in front of the nozzle is limited, but high velocity flows are possible downstream of the nozzle.

Sonic nozzles offer superior performance and stability compared to restriction orifice plates, while also providing superior pressure recovery at subsonic conditions.

It has been found through testing that an orifice plate does not properly choke, which means the mass flow rate through an orifice plate continues to increase when the downstream suction pressure is reduced. A sonic nozzle, however, will maintain a fixed mass flow rate once choking conditions occur, even if the downstream suction pressure is reduced further. This is why sonic nozzles provides better protection than a restriction orifice plates and also has a lower pressure drop in normal operation.

Sonic nozzles may also be ordered with pressure taps, allowing the nozzles to perform backup or secondary gas measurement service. They can act as both a backup measurement device in the subsonic regime, and as an overspeed protection device when choked.

Sonic Nozzle Installation

The CPA Sonic Nozzle must be installed downstream of the pipe equipment it is meant to protect. While the flow velocity in the pipe in front of the nozzle is limited, high velocity flows are possible downstream of the nozzle.

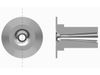

CPA Sonic Nozzles are typically installed between two raised face flanges, with a gasket on either side of the raised face disk. A portion of the nozzle will be inserted into the pipe. The location of the raised face disk determines whether the nozzle inserts into the pipe upstream or downstream of the nozzle.

A nozzle with the flange on the inlet side is designated “FOUE” and will insert into the downstream pipe. When the flange is on the outlet side, the nozzle is designated “FODE” and will insert into the upstream pipe.

The flange thickness, and the length of insertion is customizable to your needs.