- Home

- Companies

- Biocomma Limited

- Products

- Embed - CPG Technology

Embed - CPG Technology

Current oligonucleotide synthesis practice implicates stepwise addition of phosphoramidite monomers on growing oligonucleotide chains bounded to solid support. This phosphoramidite approach involves four steps for each monomer addition: de-blocking, coupling, capping and oxidation. After the desire sequence is completed, oligonucleotides are released from the support and purified, ready for downstream applications.

What’s Embed™ CPG?

Since the introduction of the phosphoramidite approach, controlled pore glass (CPG) has proven to be an excellent support matrix for oligonucleotide synthesis. Traditionally, CPG powder is packed in a synthesis column with two frits, as in Biocomma’s first generation synthesis columns. However, the traditional design has been shown to have several inherent disadvantages that inspired Embed TM technology.

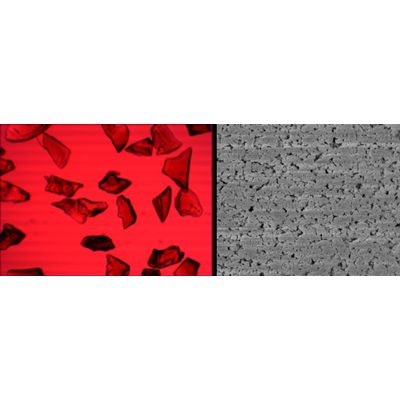

Embed TM technology utilizes Biocomma’s expertise in manufacturing small sintered polyethylene filters. When sintered with UHNW-PE or HDPE material, CPG particles are embedded into rigid PE network to form frits with defined pore sizes and porosities. The resulting CPG frits thus can be assembled in columns or well-plates to be used in automatic oligonucleotide synthesizers.

While penetrating pores within CPG particles and pores formed by PE interparticle bridging, reagent solutions flow paths long enough to increase their contact time and opportunity with reactive sites bounded to CPG surface.

As CPG particles are encapsulated and immobilized within PE particles, flow paths within CPG particles are fixed, thus leading to intimate contact of CPG and reactants which increases reaction efficiencies and improves product purities. Furthermore, this rigid porous structure generates extremely low swelling and very low back pressure variance during synthesis, giving excellent performance on automatic oligonucleotide synthesizers.

Biocomma’s Embed TM technology is an innovative solution for efficient, expedite and economical oligonucleotide synthesis.

As CPG particles are encapsulated and immobilized within PE particles, flow paths within CPG particles are fixed, thus leading to intimate contact of CPG and reactants which increases reaction efficiencies and improves product purities. Furthermore, this rigid porous structure generates extremely low swelling and very low back pressure variance during synthesis, giving excellent performance on automatic oligonucleotide synthesizers.

Biocomma’s Embed TM technology is an innovative solution for efficient, expedite and economical oligonucleotide synthesis.

Sintered with ultrapure UHWM-PE, Embed TM frits are extremely hydrophobic and favorable for phosphoramidites which are highly sensitive to water. In consequence, coupling efficiencies can be higher, mutation rates lower and error sequences less.

For full-length gene synthesis, Embed TM CPG frits make it easier to assembly fragments due to high coupling efficiencies and low mutation rates.

High overall yields

The coupling yield is key to final product yields. For example, in order to synthesize a 50-mer oligonucleotide, a coupling yield of >99% is necessary.

In addition to using high-purity solvents and reagents, there is another way to improve coupling efficiencies, i.e., to wash off residual reagents as cleanly as possible after each step of the synthesis cycle. For EmbedTM frits, a used reagent is easily flushed by a new one. For traditional CPG columns, however, a small amount of used reagent will remain within CPG powder, in equilibrium with the new one.

Thorough cleanup of residual reagents reduces chances of mutation in final oligonucleotides as well.

Time-Saving DesignDue to the unique small volume design, Embed TM CPG frits containing 0.5 - 1 mg of CPG enable efficient monomer addition with 15 - 20 μL of monomer solution. The coupling step can be finished within 30 seconds, resulting in significantly reduced total synthesis time.

With uniform flow and back pressure, CPG frits of different scales can be put into one well-plate, thus enabling high-throughput synthesis and further shortening delivery.

Flexible and Versatile- Positive pressure synthesizers, such as Dr. Oligo 192 and ABI 3900;

- Vacuum-driven synthesizers, such as MerMade 192;

- Home-made synthesizers.

Embed CPG frits can be customized to meet ever-challenging demands, such as long primer synthesis, large-scale primer synthesis and RNA synthesis.

In order to achieve each addition as completely as possible, monomer solutions should be diluted to appropriate concentrations when used. For Embed TM CPG frits, dilution factors range from 20 to 40 as reagent diffusion within frits is driven by applied pressure or vacuum which is very efficient. For traditional CPG columns, however, these numbers range from 10 to 20 as reagent diffusion within CPG powder is driven by osmotic pressure which is less efficient. Larger dilution factors definitely lead to reduced monomer usage.

By optimizing height/diameter ratios, Embed TM CPG frits are made with smaller void-space fractions, capable of reducing washing solvent consumption and waste of reactants while still keeping supreme reaction efficiencies and thorough washing.