CPM - Model CL Series -Laboratory Pellet Mills for Research and Development

The CL Series Laboratory Pellet Mills are designed to facilitate research and development in pelleting processes, supporting the testing of various formulas and materials to evaluate factors such as moisture and particle size for optimal pellet quality. These mills enable production of 30 to 200 pounds of pellets per hour and come with features tailored for in-house experimental work. The CL3 model is equipped with a hopper and a vibratory feeder with adjustable speed control, while the CL5 model includes a conditioner for steam or liquid addition, making them versatile for conducting tests with critical and expensive materials using small quantities. Compact and portable, these mills are designed to fit on an office desk and feature stainless steel contact parts for easy disassembly and sanitation. Their design allows for the adaptability of different feeders and they are supported by CPM representatives for initial setup and maintenance.

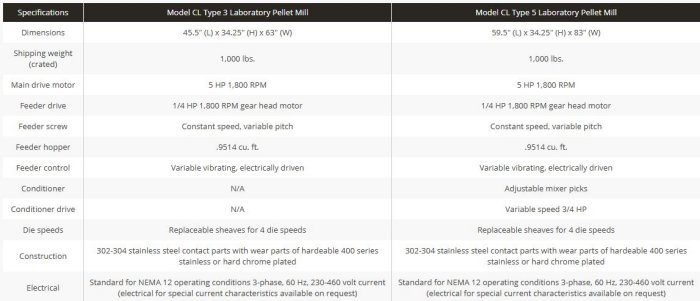

The CL Laboratory Pellet Mills are designed to test and pellet various products, allowing you to evaluate how changes in formulas affect pellet quality and production rates. The CL Series is ideal for customers aiming to produce 30 to 200 pounds of pellets per hour. The CL3 Laboratory Pellet Mill is equipped with a hopper, vibratory feeder with variable speed control, and front discharge of the pellets. The CL5 model includes a conditioner for steam or liquid addition.

Facilitates research and development

Conduct experimental work in your own laboratory with your own personnel, controlling key pelleting variables.

Saves on costs

Tests involving critical and expensive materials can be conducted with small quantities, yet yield indicative results.

Ensures ease of use

Compact, portable, and no larger than an office desk, the CL Series pellet mills are durable and trouble-free, easy to dismantle and reassemble.

Your laboratory, your personnel

Series CL Pellet Mills provide a versatile, practical answer to pelleting research and development. The mills allow you to conduct experimental work in your own laboratory with your own personnel. Models can control key pelleting variables to facilitate the evaluation of moisture, particle size, etc. Pellet sizes range from 1mm to 1/2″ diameter, in lengths of approximately 2 to 2 1/2 times diameter. Large mills can produce pellets up to 1 1/2″ diameter, round or square.

Tests involving critical and expensive materials can be conducted with small quantities, yet yield indicative results. Quantities processed may be as small as 1,000 grams.

Right at home in your lab

Compact, portable and no larger than an office desk, durable and trouble-free Series CL Pellet Mills are easy to use. They have a basic design and consist of easily dismantled and reassembled components. All stainless steel contact parts are easily disassembled and cleaned to maintain sanitary environment requirements. If required, the die can be purged at the end of the run with a compatible aseptic mix.

Your operators can quickly learn this task from your CPM representative, who will assist them during the initial setup. Your CPM sales representative will also be available when needed to maintain the best possible service from your Series CL pellet mills.

- Rotary valve for continuous flow and airlock

- Adjustable level sensor for discharge and cooling control

- Pneumatic swivel valve with three-position opening

- Octagonal design to eliminate dead angles and ensure even airflow

- 100% stainless steel construction (SUS304 or SUS316)