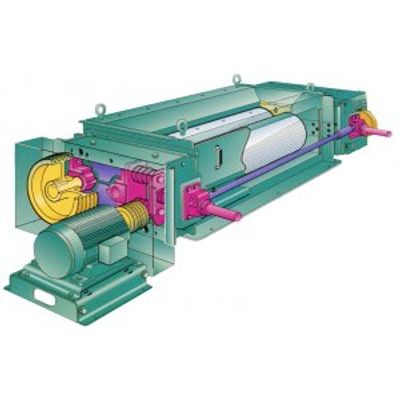

CPM - Pellet Crumblers Machines

CPM pellet Crumblers are high-capacity, high- efficiency machines. The heavy duty design and user-friendly features ensure many years of continuous, reliable operation. CPM pellet crumblers are available in a variety of capacities. As the world`s largest manufacturer of pellet mills, CPM provides the best in equipment, dies, parts and services which together represent the Lowest operating cost solution to our customers. Innovative engineering and design have been combined with the latest manufacturing technology. CPM pellet Crumblers are high-capacity (ranging from 10 to 40 t/h), high- efficiency machines. The rugged design and user-friendly features ensure many years of continuous, reliable Operation. CPM pellet crumblers are available in a variety of capacities constructed to match the output requirements of your process. Crumblers are built to operate 24 hours a day in tough running conditions.

Extensive field research has proved the CPM Crumblers can produce continuously in the most adverse conditions worldwide. The smart no-nonsense design and CPM`s high Standards ensure a long trouble-free use.

Many proven and innovative features can be found in the CPM crumblers.

- No bearing alignment is required.

- The discharge opening is the same size as the inlet, minimizing the size and height of the discharge hopper.

- There is a more robust bearing support system to handle roll separations forces.

- Full-length bolt-on maintenance doors provide full access to the rolls for inspection and adjustment.

- A safety grid is built into the inlet over the rolls.

- The inter-roll drive is spring-loaded and easy to adjust.

- With the full-feature roll adjust; Infinite adjustment of rolls is possible.

- Low profile for compact Installation.

- Different sizes are available to match your production capacities (uptil 40 tons per hour).

- More precise roll adjustment means fewer fines.

- The inter-roll drive is belt-driven; the belt tension is spring-loaded and easy to adjust.

- Dividers with bolt-on maintenance doors are standard with double stand crumbles.

- Both sides of the rolls can be adjusted simultaneously.

- Robust bearing support system handles rolls Separation forces.

- Precision machining permits accurate adjustments of the large diameter, rigid crumbler rolls.

- Best quality, hardened, chilled iron rolls for long life.

- Rugged, durable design for continuous service and long life.

- "Between the rolls" bypass on the model 1252 & 1272.

Options available

There are many different sizes and options available to match your production capacity and meet your specific requirements.

Roll adjust

- Manual hand wheel

- Air-actuated - two position

- Full feature

Feeder

- Roll feeder with lever gate

- Rotary pocket feeder

- Surge panels

Gate Actuator

- Air-actuated - two position

- Air-actuated - three position

- Full feature

- Manual handwheel

There are many different sizes and options available to match your production capacity and meet your specific requirements.

Roll adjust

- Manual hand wheel

- Air-actuated - two position

- Full feature

Feeder

- Roll feeder with lever gate

- Rotary pocket feeder

- Surge panels

Gate Actuator

- Air-actuated - two position

- Air-actuated - three position

- Full feature

- Manual handwheel

Capacity Range:

- Type 855 SS (Single Stand) - 10 tph

- Type 855 DS (Double Stand) - 20 tph

- Type 1252 SS (Single Stand) - 15 tph

- Type 1252 DS (Double Stand) - 30 tph

- Type 1272 SS (Single Stand) - 20 tph

- Type 1272 DS (Double Stand) - 40 tph

Drives:

- Type 855 SS (Single Stand) - 11 kW

- Type 855 DS (Double Stand) - 2 x 11 kW

- Type 1252 SS (Single Stand) - 15 kW

- Type 1252 DS (Double Stand) - 2 x 15 kW

- Type 1272 SS (Single Stand) - 18 kW

- Type 1272 DS (Double Stand) - 2 x 18 kW