- Home

- Companies

- Kromel Makina A.S.

- Products

- Kromel - Model UHT - Cream Cheese ...

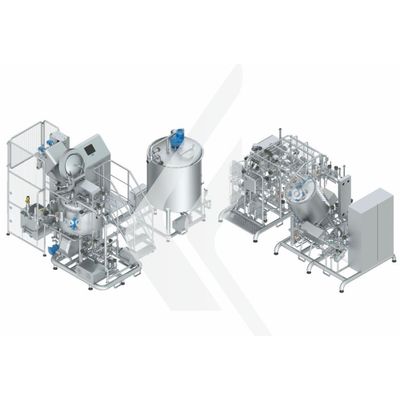

Kromel - Model UHT -Cream Cheese System

Raw Material Preparation: The product, of which the grinding and homogenization processes have been completed, the screening has been done by passing through metal detectors, the pre-processing such as weighing has been completed, and planned to be produced under the requested conditions, consists of a mixture of raw cheese, butter, fat and oils, various powders and water.

Processing

1-Pre-Heating/Homogenization

- In the batch heating system, all processes such as heating with direct steam injection and emulsification, cutting, mixing and deaeration are made in a single unit (KR-500).

2-UHT

UHT is a state of the art system that has the capacity of processing and producing many products in the same system. The products produced in this system has twice the shelf life compared to its equivalents because of heating up to 145 °C. UHT is used for this extended shelf life durations. To prevent the adhesion in the pipes due to temperature after the heating, the pipe surfaces contacting with the product are coated with PTFE (Teflon).

The product is required to be cooled and deaerated with controlled vacuum before the filling. Afterwards, the creaming tank is used to reconstruct the product structure and to improve the viscosity. The Creaming Tank is a highly efficient mixing element equipped with viscosity monitoring.

- Additional modules for CIP, steam filtration, product filtration are available.

Specifications

- The system is designed based on the needs of dairy processing industry.

- Precise and full control in cheese processing.

- Quality production with short and effective processing durations.

- Flexible and ergonomic design according to customer needs.

Advantages

- Effective heating with direct steam injection.

- Easy use.

- Increase in working duration.

- CIP easy cleaning.

- Fixed product quality.

- Viscosity control system.

- Fulfilling new market needs.

- Easy maintenance.

Applications

- Processed Cheese (Cream, Brick, Slice)

- Analogue Cheese

- Baby Food

Processes

- Emulsification (KR 500)

- Mixing (KR 500)

- Pasteurization (KR 500)

- UHT

- Deaeration (Pre-Cooling)

- Vacuum cooling-cleaning (Pre-Cooling)