- Home

- Companies

- Creative Piping Solutions (CPS)

- Products

- Creative - Model ASME B16.47 / ANSI / ...

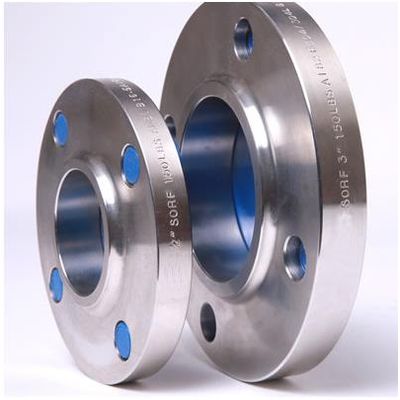

Creative - Model ASME B16.47 / ANSI / ASME B16.5 -Slip On Flange

ASME B16.47 Slip On Flange Suppliers, Series A and Series B Slip On Flange, BS10 Slip On Flange, AWWA C207 Slip On Flange, EN 1092-1 Slip On Flange Price List. ANSI B16.5 Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500 Slip On Flanges Manufacturer in India.

- Slip On Flange Tolerances & Weight Chart

- ANSI B16.5 Slip On Flange Specifications

- Why Choos Creative Piping Solutions Pvt. Ltd.

- ASME B16.47 Slip On Flange Materials

- Slip On Flange Manufacturing Process

- Slip On Flange Application Industries

- ASME B16.5 Slip On Flange Inspection

- Slip On Flange Packing & Forwarding

- Slip On Flange Export & Supply Country List

- Slip On Flange Export & Supply City List

- Slip On Flange Class 150 Dimensions

- Slip On Flange Class 300 Dimensions

- Slip On Flange Class 600 Dimensions

- Slip On Flange Class 900 Dimensions

- Slip On Flange Class 1500 Dimensions

Creative Piping Solutions are Manufacturers, Suppliers, and Exporters of Slip-on Flanges in India. We are Manufacturing high-quality Slip-on Flanges which are suitable for low-pressure applications. Our qualitative range of Slip-on Flanges is exclusively designed for several piping applications of varied industries. Slip-on Flanges that are precision engineered using the simplest quality material. We also customize these industrial flanges as per the necessities of the clients.

Slip-on Flanges are typically given a raised or flat face. When a raised face is important for slip-on pipe flanges, the quality height is 1/16″ for slip-on pipe flanges under 400#. For slip-on pipe flanges of 400# and up, the quality slip-on-pipe flange raised face height is 1/4″. Slip-on Flange is actually a ring that’s placed over the pipe end, with the flange face extending from the top of the pipe by enough distance to use a weld bead on the within diameter.

Slip-on Pipe Flanges altogether steel material grades, including carbon slip-on pipe flanges, chrome steel slip-on pipe flanges, and alloy slip-on pipe flanges. We even have many various slip-on pipe flanges available and ready to ship. Slip-on pipe flanges available include AWWA slip-on pipe flanges, ANSI Slip-on Pipe Flanges, Pressure Vessel slip pipe flanges, and slip-on pipe flanges that match the OD and drilling of ASME flanges. The slip-on flange can also be used joint flanges if type b or Type C stub ends are used.

- Flange Size ½” (15 NB) to 48″ (1200NB)

- Flange Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40.

- Flange DIN DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

- Flange BS BS4504 , BS4504, BS1560, BS10

- Flange Standard ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

- Flange Coating/Surface Treatment Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

- Flange Connection Type Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

- Flange Face Type Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

- Flange Dimensions ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Flange JIS 5K, 10K, 16K, 20K, 30K, 40K, 63K

- Flange UNI 6Bar 10Bar 16Bar 25Bar 40Bar

- Flange Coating Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

- Production technique Forged, Heat treated and machined

- Test Certificates EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc

- Flange Test Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

- Equipment Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc

- Flange Origin Indian / West Europe / Japan / USA / Korean