- Home

- Companies

- Crist Group, a HARRINGTON Company

- Products

- Crist - PFA Custom Fittings

In the world of industrial manufacturing, standard isn’t always sufficient—especially when it comes to crucial applications where precision and reliability are non-negotiable. That’s where Crist Group’s specialty fittings come into play. (These fittings aren’t just parts; they’re the backbone of systems that demand perfection). Our high-performance solutions—particularly PFA fusion welded pipe & tubing manifolds—are engineered to meet the stringent demands of industries where standard simply won’t do.

The global pipe fittings market is projected to reach $19.8 billion by 2030, growing at a CAGR of 4.2% from 2023 to 2030. Crist Group is leading the charge, not just meeting market demands but setting new industry standards.

Specialty fittings are far from being simply connectors. They are specially manufactured products that are intended to meet particular industrial uses when standard fittings are inadequate. From a semiconductor manufacturing plant where careful contamination control is of the utmost importance to a health science laboratory where purity is a must – custom fittings are important. Its performance enhancement is best embodied in Specialty Fittings because, unlike basic fittings that can be purchased in bulk and have an average quality, custom Fittings are custom-made to suit the specific needs of clients to guarantee their smartness in producing superior outcomes even in the harshest conditions on the field.

BENEFTIS OF USING SPECIALTY FITTINGS

So why choose specialty fittings over their standard counterparts? (It’s all about performance, longevity, and peace of mind.) Here’s what you can expect:

1. Superior Chemical Resistance: Materials such as PFA (Perfluoroalkoxy) have zero susceptibility to corrosion and provide high levels of chemical resistance for the long term.

2. High Purity: Manufacturing industries such as semiconductors are susceptible; even minimal impurity can lead to huge losses. Specialty fittings possess qualities that allow them to keep contamination levels at their lowest possible.

3. Improved Reliability: Custom fittings are made to fit perfectly within the system. Therefore, there are likely to be low incidences of leakage or failure.

Contact us to learn more about how our specialty fittings can benefit you!

TYPES OF SPECIALTY FITTINGS OFFERED

Crist Group offers a diverse range of specialty fittings designed to meet the specific needs of various industries. Our product lineup includes:

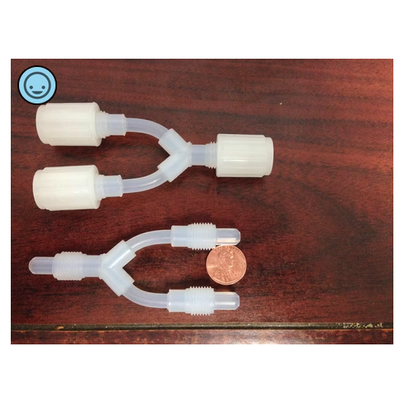

1.PFA Fusion Welded Pipe & Tubing Manifolds: Ideal for applications requiring smooth, low-depression joints, these manifolds ensure seamless connections that maintain high purity and performance standards.

2.Custom-Engineered Fittings: Tailored to your project’s unique requirements, these fittings can be customized in terms of size, shape, and material, ensuring they meet the exact specifications needed for your application.

3.Industrial Fittings: Built for strength and durability, these fittings are designed to withstand the rigors of abrasive and challenging industrial environments.

Each fitting is crafted from materials chosen for their ability to handle specific operating conditions. For example, PFA offers exceptional chemical resistance, PTFE provides superior thermal stability, and FEP is known for its flexibility. These materials ensure that our fittings perform reliably, even in the most demanding environments.

One size does not fit all, especially in critical applications. At Crist Group, we allow several customization measures to ensure that you get the desired fittings. For instance, if you require a particular size, material, or design, our engineering team shall assist you. (We don’t just deliver products—we deliver solutions.) This approach allows you to get fittings that work in harmony with your system, minimizing interruptions and increasing its smartness.

Semiconductor

Ensuring ultra-high purity in every connection.

Services tailored to the exact requirements of manufacturers with the first equipment.

Resistance of fittings to various conditions, such as harsh weather or climates.

Pipes that must conform to high levels of purity and functionality.