- Home

- Companies

- Oxymo Technology

- Products

- Oxymo - Crocheted PVDF Composite Hollow ...

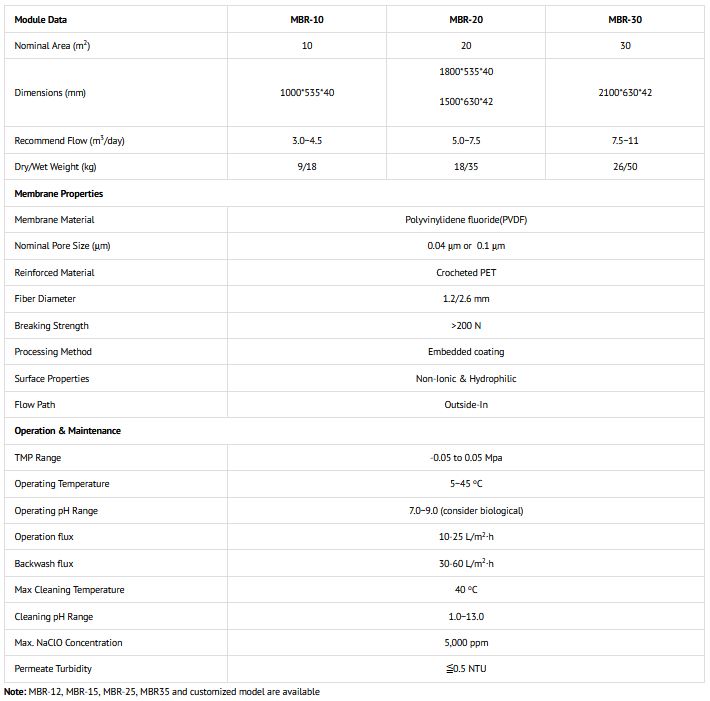

Oxymo - Crocheted PVDF Composite Hollow Fiber Membrane Bioreactor (MBR)

This technology relates to the field of composite separation membranes, mainly obtains a PVDF reinforced hollow fiber membrane bio-reactor (MBR membrane) with high strength, anti-stripping/anti-peeling, super hydrophilic and gradient pore structure.

Why We Do

With the continuous improvement of industrialization and the deterioration of the quality of various water sources, Good chemical stability, high mechanical strength, and strong anti-pollution ability have become increasingly common requirements for the performance of membrane separation materials.

At present, hollow fiber membrane bioreactor have occupied obvious advantages in global membrane bioreactor (MBR) engineering applications.The types of hollow fiber membrane bioreactor(MBR) are mainly as homogeneous solid PVDF hollow fiber MBR and reinforced PVDF composite hollow fiber MBR. First of all, due to insufficient strength, homogeneous solid PVDF membrane has the disadvantages that the membrane fibers are frequently broken and difficult to repair during operation, which will lead to poor effluent quality and extremely short service life. Therefore, the braided tube reinforced PVDF composite hollow fiber MBR are developed for the high mechanical strength required by the MBR process, which completely solved the fiber-broken situation that has been worried by waste water industry for a long time. so the market of reinforced PVDF MBR has a bright future. The braided tube reinforced pvdf hollow fiber membrane is mainly composed of a coated surface membrane separation layer and an inner core braided tube support material, which respectively perform functions of separation and high strength.

However, the smooth surface and high weaving density of the braided tube will lead to insufficient adhesion between the two materials. And it will cause the membrane separation layer to easily peel and tear from the surface of the braided tube. As a result, the water quality is getting worse and worse, and in severe cases, it may even lead to failure and scrapping of the MBR elements.

How We Improve

Improving the bonding strength between the membrane separation layer and the inner reinforced tube is the critical technology to extend the service life of the reinforced hollow fiber membrane bioreactor. In this regard, some international companies such as Japan Mitsubishi and USA Koch have also researched and produced the reinforced PVDF hollow fiber composite membranes , all their products are with relatively high anti-peeling strength.

Hydro blue’s technology mainly uses the following two aspects to improve the reinforced PVDF hollow fiber MBR membrane.

1. Use a crocheted support tube instead of a braided support tube(Figure1). The surface of the crocheted tube is rough and full of small through holes penetrating the inner surface of the support tube. By using the controllable infiltrated and embedded composite molding processing technology, the membrane material penetrates and is firmly embedded in the inner support layer(Figure2), which greatly enhances the adhesion between the membrane separation layer and the inner support layer. Therefore, The problems of fiber-broken and fiber peeling are completely fundamental solved out in current MBR applications.