CTP Chemisch Thermische Prozesstechnik GmbH / CTP Air Pollution Control GmbH

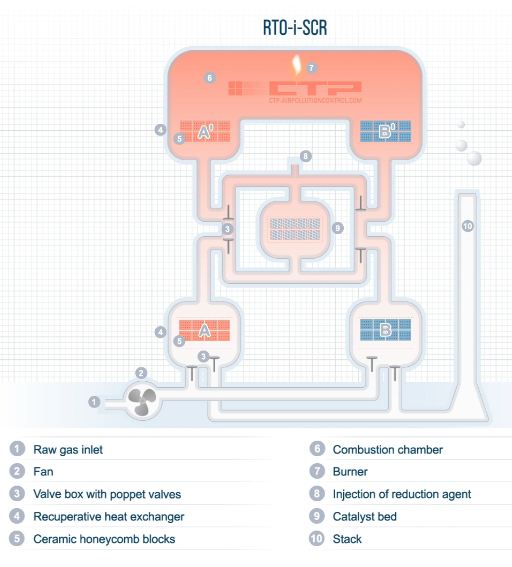

CTP - Model RTO-i-SCR / RTO + SCR -Regenerative Thermal Oxidation System (RTO)

The perfect CTP-solution for a combined cleaning of organic pollutants (RTO) and nitrogen oxides (SCR) at high efficiencies. The RTO-i-SCR is suitable for flow rates up to 300.000 Nm³/h at raw gas temperatures up to +200°C.

Most popular related searches

thermal oxidizer system

thermal oxidation

thermal oxidizer

regenerative thermal oxidizer system

SCR catalyst

regenerative thermal oxidizer

NOx treatment

organic pollution

SNCR

fouling

- Highest flexibility and possibility for extension

- Combination of proven RTO technology with catalytic denoxification in one system

- Combined VOC, CO, N2O and NOx treatment

- Highly effective SCR catalyst operated at optimum temperature

- SCR catalyst does not come into contact with the raw gas (no danger of fouling by aerosols and high boiling substances like soot or tar)

- Highest VOC cleaning efficiency

- Highest NOx cleaning efficiency

- Flexibility in the heat-exchanger design, adapted to the optimum operating range of the SCR catalyst:

- High thermal efficiency

- Low pressure-loss (20 to 50 mbar)

- Low operating costs

- Specifically designed for the respective application

- Free choice of the auxiliary fuel (possible restrictions regarding the SCR-catalyst)

- Free choice of the reducing agent

- Multifuel burner

- Gas- or liquid injection

- Electric heating

- Bake-out

- Integrated raw gas preheating

- Integrated washing device

- Special insulations and coatings

- SNCR