- Home

- Companies

- Arizona Optical Metrology

- Products

- AOM - Custom Computer-Generated ...

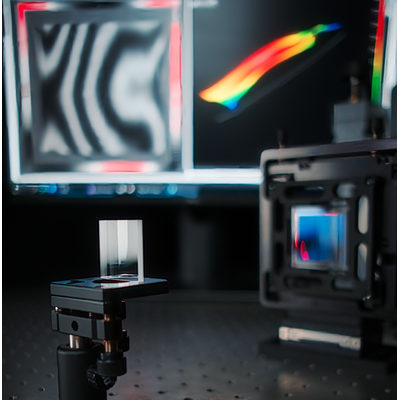

AOM - Custom Computer-Generated Holograms for Optical Surface and Wavefront Testing

Computer-Generated Holograms (CGHs) are precision-engineered optical elements that play a crucial role in advancing metrology for optical surfaces that are complex in shape. By modifying the test-leg wavefront of an interferometer, CGHs facilitate the precise measurement of a wide variety of optical surface configurations, including aspheres, freeforms, conics, and off-axis sections, overcoming the limitations found in traditional interferometry. Crafted predominantly from binary diffractive optics, these holograms are produced using lithographic techniques that enhance their precision. Available in sizes of 3-inch, 6-inch, and 9-inch, CGHs from Arizona Optical Metrology offer customizable solutions, integrating seamlessly with alignment stages and featuring anti-reflective coated back surfaces. They consist of silca substrates where the diffractive pattern is meticulously printed or etched, providing a comprehensive metrological solution when combined with a Metrology System, ensuring accurate surface and wavefront analysis.

A cylinder CGH (or computer-generated hologram) is a diffractive optical element that converts a collimated interferometer wavefront into a converging cylindrical wavefront. A range of concave and convex cylindrical optics can be measured in a confocal null test with the same CGH. Position convex cylindrical optics in the converging wavefront and concave cylindrical optics in the diverging wavefront.

- Requires collimated input beam from interferometer

- Square or circular null pattern depending on size format

- Retro pattern for easy alignment to interferometer

- 633 nm operating wavelength

- Antireflection coated back surface for rejection of unwanted reflections

- Mechanical cell with stainless steel mounting balls to interface to AOM 6 degree-of-freedom alignment stages