- Home

- Companies

- T&C Mfg & Operating Inc

- Products

- Custom Rubber Molding

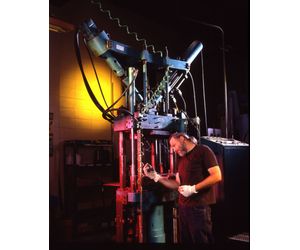

Custom Rubber Molding

T&C utilizes compression, injection, transfer compression molding, and rubber to metal bonding processes to manufacture custom rubber molded parts. In order to meet customer requirements, T&C will provide tooling and die cutting for mold design and prototyping at reasonable prices and quick turnaround for custom parts, irrigation and oilfield applications. T&C is centrally located in the USA for convenient shipping. Centrally located in Great Bend, KS, T&C employs qualified technicians with more than 60 years of experience in the design and development of custom rubber molds to direct the engineering of all products moving through production.

Our qualified staff can custom design simple or complex parts to meet critical dimensions and usage covering a broad range in every industry. Some of the numerous custom parts we have manufactured include toy tires, bumpers for carts on assembly lines, light fixture gaskets, brake pads, casing wipers used in the oilfield and saw guards for removing plaster casts. Please click on the “CONTACT US” tab above to allow the T&C MFG & Operating, Inc. team to help you with you custom molding needs.

Our expertise allows us to manufacture rubber parts from a variety of compounds, including:

- EPDM– very resistant to weathering and ozone, good to very good aging resistance and low temperature flexibility, low electrical conductivity and resistance to polar chemicals. It is used most often in the construction and automotive industries.

- Viton-is the most specified fluorelastomer, known for its excellent (400 F/200 C) heat resistance. It offers excellent resistance to aggressive fuels and chemicals. This compound is used extensively in application including automotive, fluid power devices, industrial appliances and chemical plants.

- Natural-with a smooth finish, superior abrasion resistance, high tensile and elongation characteristics it is used in many applications and products. It resists most organic salts, acids, alkalis and ammonia and is extremely waterproof.

- Neoprene-maintains its strength, flexing, twisting and elongation well over a wide temperature range

- Nitrile (Buna N)-a copolymer of butadiene and acrylonitrile. In addition to its excellent elastomer properties, it is resistant to oil, caustics, and aliphatic hydrocarbons. Nitrile is not suitable for solvents and chlorinated hydrocarbons. It’s maximum temperature limit is 212

- SBR (styrene-butadiene rubber)-very economical and possesses no unique chemical resistance properties. This rubber can be compounded to provide very fine abrasion, wear and tensile qualities and often substituted for natural rubber in many applications with significant cost savings. A staple in the HVAC and construction industries, this is a good choice when deciding to choose a material that has mechanical properties and flexibility.

- Silicone-this rubber is inert, very flexible and can be used in medical and FDA environments. In addition to temperature, silicone has superior resistance to water and works well as an electrical insulator.