Genesis Attachments, LLC

- Home

- Companies

- Genesis Attachments, LLC

- Products

- Cyclone Specialty Attachment

Cyclone Specialty Attachment

In trenching, concrete removal and other rock-based applications, the Genesis Cyclone combines power, performance and versatility to dramatically outperform traditional processing tools, such as hydraulic hammers, with a fraction of the noise and vibration.

Most popular related searches

noise and vibration

soil remediation

concrete remover

hydraulic hammer

construction vibration

river bed

secondary crushing

pipe laying

crushing equipment

soil blending

The Cyclone’s:

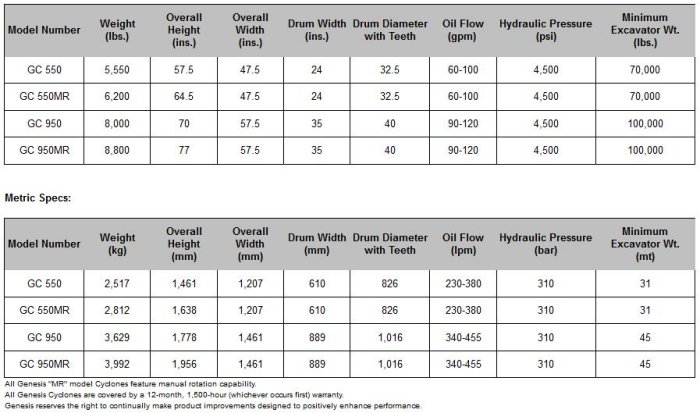

- Mounting bracket is easily installed on and removed from a range of 60,000 to 150,000 lb. excavators

- Single, 24- or 35-inch wide drum maximizes material processing per pass

- Performance-driven tooth pattern ensures optimum processing capabilities

Because the Cyclone’s an ideal alternative to traditional processing methods, contractors can expand their operations by handling diverse projects and applications.

- Trenching/Channeling - In solid rock

- Pipe Laying Easily lay pipeline in a fraction of the time demanded by traditional methods such as breakers

- Quarry Work - Generate 8-inch minus range product, eliminating primary, and in some cases secondary, crushing equipment

- Demolition - Demolition and processing of even the highest-strength wall, slab, footing and bridge abutment concrete

- Stump Processing Easy and efficient land clearing

- Tunneling/ Mine Work - Safe, controlled tunneling as well as mine profiling, mineral extraction, heading and ripping

- Commercial/Residential Construction Vibration-free operation for basement excavation or foundation milling applications

- Soil Remediation Easily change-out teeth with alternative wear parts such as paddles for fast, effective contaminated soil blending and remediation

- Milling - Trenches, river beds, concrete and asphalt

- Highway and road building

- Slag Processing

- Pin-on carbide teeth rotate while cutting for even wear and a better grinding point

- Heavy-duty hydraulic motor and gearbox with a direct drive system ensure solid performance

- Manual rotation, MR, models can be locked into one of four positions

- Short, two-piece rock shield allows easier use in narrower trenches

- Manual rotation (MR) models can be locked into one of four positions

- Short, two-piece rock shield allows use in narrower trenches

- Pin-on carbide teeth rotate while cutting to allow even wear and a better grinding point

- Fully enclosed hydraulic components

- Heavy-duty hydraulic motor and gearbox with a direct drive system ensure solid performance

Applications

- Trenching

- Quarry Work

- Demolition

- Tunneling & Mine Work

- Soil Remediation

- Lock & Dam Reconstruction

- Concrete Milling/Resurfacing

- Waterfront Rejuvenation