- Home

- Companies

- Advanced Engineering Wedge Wire

- Products

- ADENWEDGEWIRE - Cylinder Wedge Wire ...

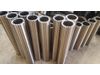

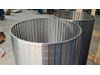

ADENWEDGEWIRE - Cylinder Wedge Wire Screen

The key product for heavy-duty filtering, centrifuging and high efficiency. Provides outstanding performance in almost every industry and application. Cylindrical wedge wires are the most popular screens that can be adapted to many applications. The shape of the cylinder helps the filtration process complete accurately.Advantages

The modular and configurable design

Maintains strong and efficient filtration

Surface Treatment based on Application

Optimized collection and distribution

Tilted Wedge Wire Placement

Corrosion-resistant

Low-pressure drop

High mechanical strength

4 configurations are available for the cylindrical wedge wire screens:

Two flow directions and two-wire axis; From Inner to Outer flow with axial or radial wires

Cylindrical wedge wires are manufactured in different dimensions depending on the application. water industry, petrochemical, food and beverage.

Typical Applications:

Wastewater treatment

Hydroelectric systems

Water Intake Systems

Food processing

Micro filtering

Self-Cleaning Filtration

Our wedge wire screens focus on full customer satisfaction in terms of competitive cost, short shipping time and high mechanical properties. Manufacturing consists of robotic systems that enable high precision and flexible solutions.

The quality control department continuously inspects and reports the whole process from receiving to final inspection to verify supplied materials conform to the proper standards, specifications and chemical composition.

Our products are manufactured with Stainless Steel 304, 304L, 304HC, 316, 316L, 316Ti, 321 or depending on your request for the different types of material with different kinds of surface treatments and coatings.