Flottweg Sedicanter - Model S3E/S4E/S6E -Decanter Centrifuge for Soft Sediment

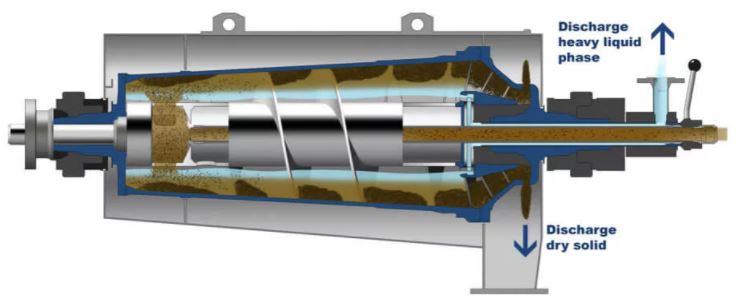

The Flottweg Sedicanter for processing fine-grained, past-like products. Flottweg produces a special decanter centrifuge for soft, easy-flowing sediment. The Flottweg Sedicanter separates solids from liquids. The special thing about it: The solids consist of a soft to easy-flowing sediment. Soft or easy-flowing solids are difficult to process with a standard decanter. Only the patented Flottweg Sedicanter achieves an optimal result. Thanks to its adjustable impeller, it achieves the best possible selectivity even with fluctuating feed rates.

The Sedicanter combines the advantages of disc separators and decanter centrifuges. It clarifies the suspension in a similar way to a separator, i.e. it provides an optimally clarified centrate. At the same time - like the decanter - it takes large quantities of solids at the inlet and produces dry solids (sediment) in the discharge.

Flottweg has been building the Sedicanter for 20 years. We offer you a wealth of experience and numerous well-known references all over the world. Our Sedicanter is characterized by outstanding performance, high quality and its long service life.

The Flottweg Sedicanter functions in a similar way to a solid bowl scroll centrifuge (decanter centrifuge). The rotation of the centrifuge generates a centrifugal field. This causes the heavy solid particles to be thrown outwards onto the bowl. The liquid collects inside after the scroll conveyor. The scroll conveyor rotates at a differential speed relative to the bowl. It thus transports the separated solids to the solids discharge of the Sedicanter.

Due to its design, the Sedicanter - like the decanter - can process high solids contents in the feed. The difference to a decanter centrifuge lies in the composition of the mixture to be processed. In contrast to a decanter, the Sedicanter also processes fine-grained, paste-like solids, which are difficult to discharge from a decanter due to their consistency.

- high loads of solids in the inlet

- good compensation for solid material fluctuations in the inlet

- high separation rates and high clarification efficiency

- Hygienic design available

- CIP cleaning possible

- Use of high-quality stainless steel

- Special construction that avoids hard to clean areas

Depending on the requirements, the Sedicanter® is available in a hygienic or inerted version. The hygienic design is mainly used in the chemical, pharmaceutical and food industries. An inerted version is necessary if media are processed whose vapors form an explosive mixture with oxygen, e.g. solvents. In an inerted operation, inert gas seals the separation chamber from the ambient air.

- Flexibility in the event of a fluctuating composition of the feed product by means of the adjustable impeller

- Inerted operation or hygienic design is possible

- Torque-dependent and infinitely variable control of the bowl and differential speed

- Adaption during operation

- Process automation possible

- All important process parameters at a glance.

The processing of lupines is equally demanding for man and machine. Especially the separation of bitter substances and dietary fibers on an industrial scale posed a great challenge.

The Prolupin GmbH uses the patented Sedicanter in addition to Flottweg decanter centrifuges to recover protein. Learn more in this video.

Features for process optimization

Adjustable impeller

In the Sedicanter®, the heavy liquid phase is discharged under pressure via an adjustable impeller. The impeller can be adjusted during operation and can be optimally adapted to changes in inlet product properties. Exact and variable adjustment of the pond depth is possible, as is the automation of the adjustment process.

Decanter bowl

The medium reaches the maximum speed in the decanter bowl, which causes the solids to settle on the inner wall of the bowl. The decanter bowl of our Sedicanter® is specially designed for the processing of soft, easy-flowing material. The Sedicanter® bowl is characterized by a high clarifying volume, a long clarifying section and high centrifugal forces.

Simp Drive

The Simp Drive® drive regulates the differential speed between the decanter bowl and scroll as a function of the prevailing scroll torque. The differential speed determines the residence time of the solids in the bowl and thus has a considerable influence on the separation process. Simp Drive® offers high economic efficiency due to a consistently high dry solids value (DS).

Materials

Components of Flottweg centrifuges that come into direct contact with the medium to be processed (including bowl, scroll and inlet), are made exclusively of high-quality, rust and acid resistant stainless steels. The Sedicanter® may be used in the food or pharmaceutical industries, etc., because the materials used meet the requirements of hygienic design.

S3E

- Dimensions [mm/ft]*: 2300x800x800 / 7,54x2,59x2,46

- Weight [kg/lb]*: 1010 / 2222

S4E

- Dimensions [mm/ft]*: 3.200x1000x1200 / 10,56x3,28x3,94

- Weight [kg/lb]*: 2400 / 5280

S6E

- Dimensions [mm/ft]*: 4500x1800x1300 / 14,89x5,81x4,17

- Weight [kg/lb]*: 8250 / 18150

* The values are approximate and may differ from the actual values.

Chemical and pharmaceutical industries

Sedicanter makes it very efficient to separate biomass from fermentation liquor.

Fats, oils, biofuels

The Sedicanter ensures greater efficiency in algae harvesting and the processing of fish and fish by-products.

Beverages

In beer production, the Flottweg Sedicanter reduces beer losses and thus increases the yield.