DEL Corporation

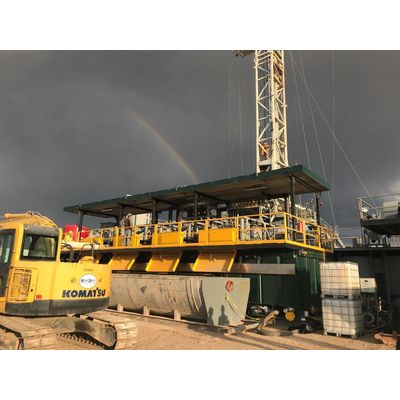

DEL KODIAK - Total Clean Mud System

FromDEL Corporation

The KODIAK TOTAL CLEAN Mud System (U.S. PATENT 10,857,488) takes mud cleaning and solids control to another level with its unique design and process flow. Rig shakers, settling pits, and drying shakers are obsolete and unnecessary. The KODIAK takes the mud directly from the rig flowline, cleans the mud and dries the cuttings. The clean mud from the Kodiak then equalizes with the rig intermediate tank. The KODIAK is the system mud companies, waste disposal companies, diesel suppliers, and screen suppliers hate. Watch the video above and then call a DEL sales representative to learn how it works.

Most popular related searches

mud cleaning system

polyurethane screen

stainless steel mesh screen

solids control

baffle system

tank cleaning

waste disposal

steel wire screen

manifold valve

stainless steel mud valve

- Lower Mud costs due to reduced mud on cuttings.

- Lower Diesel dilution costs due to more efficient removal of low gravity solids.

- Lower Disposal Costs due to dryer cuttings.

- Substantially Lower Screen Costs due to use of polyurethane screen panels.

- Longer mud motor life and fewer trips due to cleaner mud.

- Solids that normally settle in the sand trap of conventional mud systems that have to be dumped along with valuable mud are removed and dewatered (dried) by the TOTAL CLEAN Mud System.

- Undesirable solids that don’t have enough time to settle in conventional mud systems do settle in the TOTAL CLEAN Mud System due to increased settling area and the tilted plate baffle system.

- No elaborate manifolds, extensive valving, mud guns, mud ditches, or dump gates required.

- Minimizes operator decisions due to unique process flow.

- Minimizes screen costs by allowing the use of a combination of polyurethane and stainless steel wire mesh screen panels. The screen life of polyurethane screen panels is six months or longer in most applications.

- By utilizing more efficient hydrocyclones capable of running up to 3" apexes, plugging and roping of cyclones is eliminated and low gravity solids are minimized.

- The V-Tank with the shaftless auger system and the round bottom overflow compartment make tank cleaning fast, simple, and inexpensive.

- The unique process flow of the system allows coarser mesh polyurethane screen panels to be run on the Scalping Shakers and therefore produces dryer cuttings. Dryer cuttings are also realized due to the increased screening area of all shakers (50 sq. ft. each) and the use of “The Dam Thing” (patent pending) which increases the retention time on the screen without degrading the cuttings.

- Fast rig up due to modular configuration of equipment platforms.

- Touch Screen monitoring for operator provides system status in real time.