IMI plc

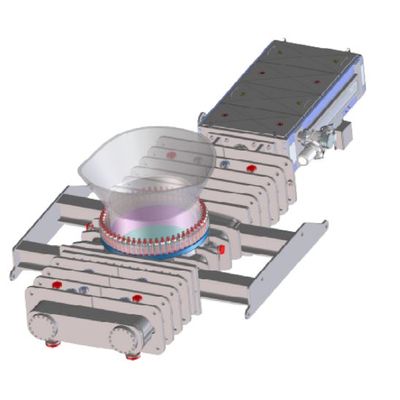

Delayed Coking Bottom Unheading Compact Design

FromIMI plc

The Bottom Unheading device is based on our well-proven Double Disc Gate Valve Design. Its fully automated compact design is the safest, most robust, and reliable solution for the Delayed Coker Application.

Most popular related searches

- Compact Valve Body - smaller face-to-face dimensions and less weight.

- Two independent discs => limited thermal distortion => less steam => less erosion.

- Two independent discs => true double block and purge.

- Two independent discs and multiple seal result in lowest steam consumption.

- Very low steam consumption

- = > high energy savings

- = > environment safety.

- Less corrosion & wear due to resistant hard-faced seats.

- Guided carrier between two plates

- => preventing coke fines in valve body > no cooling water required.

- Easy inspection of upper seat & disc.

- Minimal spare parts.

- 100% actuator redundancy.

- Actuator options: electric or hydraulic.

- Low potential for HC`s escaping to the atmosphere.

- IMI Z&J`s DC Revamp Solution.

- Easy-on deck maintenance.

- Low maintenance with minimal downtime.

- Low steam consumption.

- Cycle time reduction - optimized production output.

- Fully remote operation, no operator on deck during unheading.

- True double block & purge - 2 independent discs provide individual sealing.