IMI plc

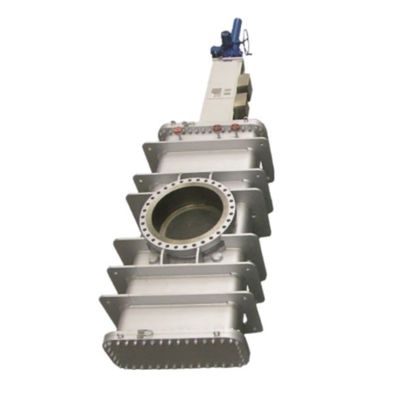

Delayed Coking Top Unheading

FromIMI plc

The DC Top Unheading device design is based on our well proven ond multiple used Double Disc Through Conduit Type Gate Valve. Its properties were increased for the higher demand for pressure and frequent tightening performance in the delayed Coker application.

Most popular related searches

through conduit gate valve

through-conduit gate valve

gate valve

fugitive emissions

cooling water

water cooling

maintenance inspection

electric actuator

- Two independent discs =>l_imitcd thermal distortion => less steam => less erosion.

- Two independent discs => true double block and Purge.

- Active mechanical seating force => high tightness.

- Corrosion & wear resistant hard-faced seats.

- Guided carrier between two plates => preventing coke fines in valve body.

- No cooling water required.

- Minimal spare parts.

- Actuator options: Electric or Hydraulic.

- Low potential for HC`s escaping to the atmosphere due to two (2) disc design (double isolation barrier).

- Safety - Double Block and Purge - API 598 shutoff.

- Low steam consumption.

- Reduction in fugitive emissions.

- Reliable design.

- Easy On-Deck inspection and maintenance.

- Low maintenance cost.

- Cycle time reduction.