- Home

- Companies

- Devise Engineering S.A.

- Products

- Devise - Model ex-MBR - Packaged Plants ...

Devise - Model ex-MBR -Packaged Plants for Industrial Wastewater & Leachate Treatment

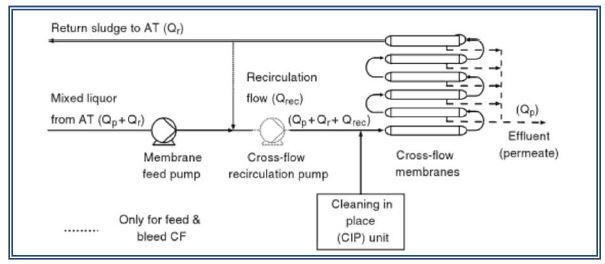

The "ex-MBR" type Package Plant is used for extensive solids separation of biologically treated wastewater. The DEVISE ex-MBR plants incorporates an energy efficient “cross-flow” type Ultra Filtration (UF) membrane module and associated equipment and instrumentation to achieve a reliable and effective filtration process. The ex-MBR plant is a compact separation unit, with all the necessary equipment (membranes, pumps, plumbing fittings & piping, control & automation, instrumentation monitoring operation) fully integrated in a specially constructed for this purpose container. The DEVISE ex-MBR package plant also includes the necessary lighting, ventilation, insulation and other necessary facilities to form a complete system ready for installation on the industrial plot of each industry and directly connected to the bioreactor.

ex-MBR Plant Packaged Plant for Industrial Wastewater Treatment –exMBR Technology with Cross-Flow membranes

DEVISE ENGINEERING S.A. specializes in the design and manufacturing of innovative Package Wastewater Treatment Plants. In order to deal with heavy polluted wastewater arising mainly from industry but also from other sources such as landfill sites and solid waste treatment facilities, DEVISE ENGINEERING S.A. has developed and manufactures a Containerised Unit of advanced solids separation which has great advantages in implementation of Industrial Wastewater Treatment Plants.

The "ex-MBR" type Package Plant is used for extensive solids separation of biologically treated wastewater. The DEVISE ex-MBR plants incorporates an energy efficient “cross-flow” type Ultra Filtration (UF) membrane module and associated equipment and instrumentation to achieve a reliable and effective filtration process. This Technology has been very successfully used for several decades in numerous hard-to-treat industrial wastewaters such as leachates from landfills, oil extraction, electronics and pharmaceutical industries as well as tanneries and others. The UF membranes modules used in the DEVISE Plants are supplied from 1st Class European Manufacturers with great experience in this type of equipment.

The DEVISE ex-MBR package plants are designed to be fed with liquid mixed with solids concentration up to 15 g / L, from the bioreactor installation which will be designed in such a way as to fully address the incoming pollutant load (COD and ammonia). The ex-MBR Plants are manufactured as full prefabricated systems inside specially modified containers, with capacities from 25 to 200 m3/day per unit (container). Combining several systems, containerized units, in parallel can process higher capacity of wastewater.

The ex-MBR plant is a compact separation unit, with all the necessary equipment (membranes, pumps, plumbing fittings & piping, control & automation, instrumentation monitoring operation) fully integrated in a specially constructed for this purpose container. The DEVISE ex-MBR package plant also includes the necessary lighting, ventilation, insulation and other necessary facilities to form a complete system ready for installation on the industrial plot of each industry and directly connected to the bioreactor.

The Prefabricated DEVISE ex-MBR Plants offer many advantages over conventional MBR systems of submerged membrane type (immersed MBR) and the most important of them are the following:

- Very compact installation due to the ability of UF membranes to operate at high flux rates (60-100 LMH)

- Reduced bioreactor volume requirements due to the ability to operate at high concentrations of suspended solids (12-15 g/L in the bioreactor, up to 18 g/L in the recirculation loop)

- Use of high strength and durability pressurized membrane modules for highly polluted wastewater applications

- Reduced chemical cleaning requirements for membranes due to their self-cleaning capabilities through the cross-flow mechanism

- Easy accessibility for maintenance or replacement of membranes

- Low energy requirement due to the absence of air scouring for cleaning

- Treatment Capacity up to 200 m3/day

- Installation in specially modified container High-Cube 40 ft (12 m) including the following basic equipment:

- Rack of horizontal cross-flow membrane modules

- Mixed fluid recirculation pump (recycle pump) pressure 3.5 bar (with standby where required)

- Pump and dosing vessel with NaOCl (with standby where required)

- Pump & Dosing vessel for citric acid (with standby where required)

- Hydraulic accessories and fittings

- Instruments for monitoring & control of operation (pressure sensors, filtrate flow meter, in-line filtration trough)

- Control Panel and automation with PLC