- Home

- Companies

- Poly Processing Company

- Products

- Poly Processing - Diesel Exhaust Fluid ...

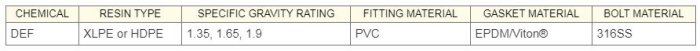

Poly Processing - Diesel Exhaust Fluid for Chemical Storage

A urea-based chemical reactant designed specifically for use in SCR systems to reduce NOx emissions. To meet 2010 EPA regulations in North America, most producers of diesel engines have announced plans to use Selective Catalytic Reduction (SCR) technology, requiring Diesel Exhaust Fluid (DEF). DEF is essentially a mixture of water and urea. In diesel vehicles, you pump a controlled amount of DEF into the exhaust stream; there the DEF is converted to ammonia. The ammonia then breaks down nitrogen oxides, significantly reducing pollution.

- Diesel Exhaust Fluid (DEF) is a high purity chemical fluid and should be treated similarly to engine oil.

- Never store Diesel Exhaust Fluid (DEF) in old oil or diesel tanks.

- Never add anything to Diesel Exhaust Fluid (DEF). For example adding water to Diesel Exhaust Fluid (DEF) will damage your SCR system and could void your vehicle warranty.

By providing the right kind of storage for this chemical, safety can be maintained – and the integrity of the product can be preserved.

Several of Poly Processing’s features can make your storage system work for handling DEF. An IMFO® system is ideal for ease of cleaning and preventing contamination, since the tank drains at its true bottom. Heat pads and insulation can help keep the chemicals at the optimal temperature, greatly reducing the chance of separation and settling.

For additional information on storing diesel exhaust fluid, including recommended storage tanks and components, download our Diesel Exhaust Fluid Guide below. Or, download the Tank Designs & Specifications Guide to see all of our chemical storage products.

- High-density crosslinked polyethylene (XLPE) for long term durability.

- Integrally Molded Flanged Outlet (IMFO®) for easier cleaning and better product utilization.

- Heating pads and insulation for maintaining chemical integrity.

- SAFE-Tank® if secondary containment is needed.

Tank

IMFO® Vertical Flat Bottom of XLPE:

- 200–13,650 gallons

- 1.3, 1.65, 1.9 spg rating

Non-IMFO® alternative:

SAFE-Tank® XLPE:

- 55–8,700 gallons

- 1.3, 1.65, 1.9 spg rating for primary tank

- Spg ratings for secondary tanks ≥ 3,000 gallons may be equal to or 1 less spg than primary tank.

- All other tank sizes must equal primary tank spg rating.

Standard Vertical Flat Bottom XLPE:

- 30–13,650 gallons

- 1.3, 1.65, 1.9 spg rating

Horizontal Tanks:

- 65–2600 gallons

- 1.3, 1.65, 1.9 spg rating

Plumbing to the tank

- Required use of flexible connections with fittings on lower third of sidewall

- Allows for lateral and vertical expansion and contraction of the tank

- Reduces pump and piping vibration stress on the tank

- Expansion joints must meet the following minimum requirements:

- Axial Compression ≥ .67"

- Axial Extension ≥ 0.67"

- Lateral Deflection ≥ 0.51

- Angular Deflection ≥ 14°

- Torsional Rotation ≥ 4°

Venting

Foundation and restraints

- PPC IMFO® tank pad or smooth concrete, asphalt or solid steel foundation designed to accommodate IMFO®, SAFE-Tank® or vertical tank

- No restraint or ladder attachment bands circumscribing the tank are allowed. Cable restraint systems must pass cables over the top of the tank.

Temperature

Product should not exceed 100°F at delivery or during storage to maintain ASTM D1998 design parameters. Contact Customer Support if chemical is to exceed 100°F.

Lid

Bolted manway cover

Options

Restraint systems for wind and seismic, level gauges, ladders, heating pads, insulation, fume-tight manway and engineering stamp