- Home

- Companies

- Microrite Cleanroom Solutions

- Products

- Microrite - Diffuser Manifold System

Microrite - Diffuser Manifold System

A Diffuser Manifold is required to properly introduce the Tracer Particles into a cleanroom. Inside the manifold the vapor cools and mixes with air forming a stable fog at ambient temperature and pressure while avoiding fully condensing back into a fluid. This removes the jetting effect of shooting the Tracer Particles in a single direction (Often Downward) that may falsely demonstrate unidirectional airflow when dead spaces and eddy currents are apparent. In addition, excess condensation of the Tracer Particles on surfaces in the cleanroom is avoided since the fog exits the manifold at the same temperature and pressure as the cleanroom environment. (3) Water, CO2 or Nitrogen Based “Cleanroom Fogging Systems” Tracer Particles are NOT Neutrally Buoyant and cannot visualize dead spaces or areas where there is no air flow.

A fully Configurable Diffuser Manifold System that converts hot vapor into a stable in situ fog at atmospheric temperature and pressure

(3) CETA Certification Guide for Sterile Compounding Facilities CAG-003-2006 -13 Revised May 20, 2015

For cleanroom applications, particles which are Neutrally Buoyant are influenced only by air currents within the cleanroom or area being tested. Gravity and the particle cloud temperature and pressure do not influence their behavior during the testing.

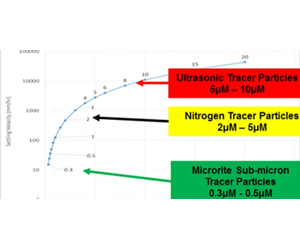

Microrite’s Tracer Particles have a Very Low Settling Velocity compared with Water CO2 or Nitrogen Based “Cleanroom Foggers”

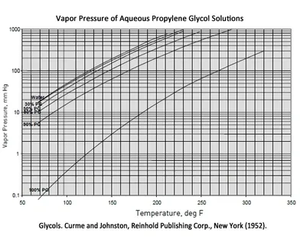

Vapor Pressure

Water, CO2 or Nitrogen Based ”Cleanroom Foggers” produce a high vapor pressure particle cloud that evaporates rapidly under normal atmospheric conditions and condenses rapidly once the cloud reaches its saturation vapor pressure.

References

Why are other Cleanroom Foggers Unsuitable for Testing Medical Product Cleanrooms?

Per CETA Certification Guide for Sterile Compounding Facilities CAG-003-2006 -13 Revised May 20, 2015 Section 13.5:

- Water based fog generators such as CO2 and liquid nitrogen create a fog that is heavier than air and do not always provide for an accurate representation of the actual air patterns.

- The smoke source should be as close to neutrally buoyant as possible. For example, when generating the fog in an area with no detectable airflow, it should not “fall out” or “drop”.

- Fog streams that are heavier than air may not detect updrafts and turbulence that are detected with a generally neutral buoyant detection stream.

The Controlled Environment Testing Association (CETA) is specifically referenced in USP 797 Section 5: Certification and Re-certification:

Before a compounding area is used to compound either Category 1 or 2 CSPs, it must be certified using procedures in the current Controlled Environment Testing Association (CETA) Certification Guide for Sterile Compounding Facilities or an equivalent guideline.