- Home

- Companies

- COMAFER Macchine S.p.a.

- Products

- Dinamic - Model 110S - Sbriquetting ...

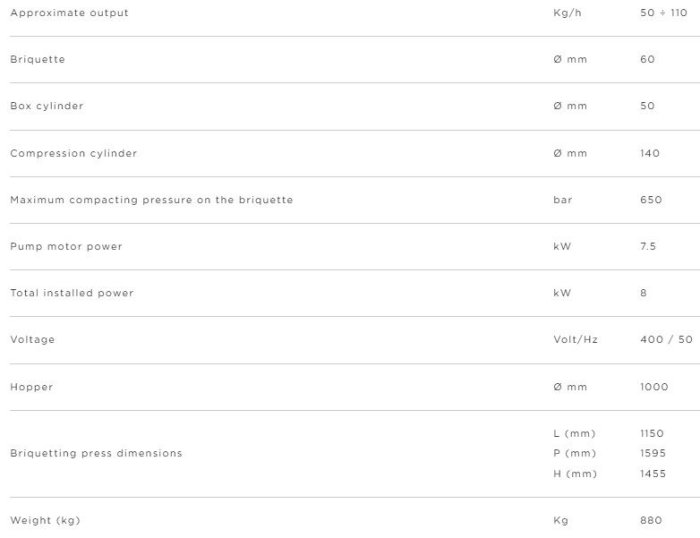

Dinamic - Model 110S -Sbriquetting Press

This product is a hydraulic machine for recycling wooden chips, sawdust, powder and ground scrap, depending on the screen mounted on the grinder, (the best moisture content should be between 8%–17%) coming from joineries, and transforming them into cylindrical briquettes without adding any binder or chemical additives offering considerable advantages. It is designed for being applied also to silos or filtering batteries indoors or outdoors.

Function is based on a mechanical and hydraulic cycle of high-pressure compacting. A material loading hopper with flush steel wheel stirrer on the bottom that rotates, ensuring the material is loaded into a box by a hydraulic cylinder with pre-compression function before the material reaches the compression chamber. A special hydraulic compression cylinder then compresses the material in the sleeve-extrusion pipe unit.

Reduction In Volume -90%

Briquettes allow for sensible reduction in volume (depending on the type of material) due to their high pressure compactness rather than the chips. They make work environments considerably more organised and efficient. You can use new spaces to store products and for the production lines.

Lower Handling and Transport Costs -80%

The briquettes ensures easy and practical handling, thus reducing internal and external transport costs (use of the forklift truck and, consequently, the time operators dedicate to collecting scraps).

Lower Recycling Costs -70%

The lower transport costs for briquettes have a direct impact on the sales margin at the collection facilities and can represent a valuable source of income.

Lower Environmental Impact

Briquettes allow for reducing the environmental impact due to the conditions and state of the container or collection facilities, which are often not in a good state.

Lower Environmental Pollution -70%

The briquettes improve combustion in boilers and fireplaces thanks to an exceptional heat capacity. In turn, this sensibly optimises the yield resulting in less fumes generated and very limited post-combustion residues.

Higher Yield +80%

The briquettes allows for concentrating high energy reserves in a limited volume with a high environmental conservation. During the combustion phase into boilers and fireplaces, the briquettes increase the yield quite sensibly owing to their fundamental characteristic of being compacted at extremely high pressures, as opposed to plain wood chips or shavings. Due to their exceptional heat capacity (wood briquettes have an average yield of 4,000/4,500 kcal, higher than of firewood, which is 2,000/2,300 kcal), they retain heat for longer keeping the temperature inside the boiler`s firebox high. Owing to their physiological properties, they are ecofriendly, produce little smoke, have a high density, low percentage of humidity and burn slower and almost entirely with a very limited post-combustion residue. The boilers are cleaner and require less maintenance. Due to the very low porosity of briquettes, the embers produced during combustion are denser than to the ones produced by wood or by non-pressed biomass.

Loading Unit

The loading unit has been designed for optimum functionality, with a material loading hopper with flush steel wheel stirrer on the bottom that rotates via a mechanical device managed by the movement of the compressor cylinder, ensuring material is fed into a fixed chamber containing a moving box.

Base Unit And Oil Tank

Base unit and oil tank designed and built with thick sheets and tubulars for superior resistance to stress that has been arc welded and powder coated. In addition to its support function, it also acts as the oil tank for hydraulic components. Mounted on the base unit is an IE3 Premium efficiency electric motor, connected to a Casappa hydraulic pump to pressurise the system, an oil filtration device, an output pipe with air filter and for oil refill, a max. oil temperature thermostat and an electrical oil-level sensor that stops the machine in the event of a leak.

Box Unit

The box unit has been projected with excellent build quality and reliability criteria. It is composed of a hydraulic cylinder with lapped housing and Parker seals, whose position is detected by proximity switches to optimize the exchanging time of the electrovalves). It activates the adjustable moving drawer to portion and pre-compress the material, from the loading hopper to a compression chamber.

Compressor Unit

The compressing unit has been projected with excellent build quality and reliability criteria. It is composed of a hydraulic cylinder with Parker seals, whose position is detected by a mechanical limit switch), and a piston rod to compress the material in a sleeve inside the compression chamber and shape the briquette.

Vice Unit

Vice unit composed of a CNC machined single-body vice with high-quality, high-reliability hydraulic cylinder and Parker seals and guide rings which holds and releases an extrusion pipe within which the briquette is held during the compression phase and released once the specific pressure required for briquette is reached. A dedicated pressure gauge allows control of vice operating pressure.

Hydraulic Components

Entirely exclusive hydraulic components with high-performance and high-reliability manage the operating phases of the machine`s briquetting cycle, optimising hourly yields. An exclusive block (manifold master) acts as a connection node for all hydraulic components. The movement and operating sequence of the cylinders is managed by two Eaton electrovalves.

Electric Control Panel

State of the art IP 55 high technological and functional electric control panel equipped with brand new Eaton PLC (Industry 4.0) for the electronic control of the production process able to connect with computer`s systems. The PLC is equipped with pressure discharge programme for progressive start-up. A digital thermostat controls the oil temperature.