- Home

- Companies

- COMAFER Macchine S.p.a.

- Products

- Dinamic - Model 70N - Briquetting Press

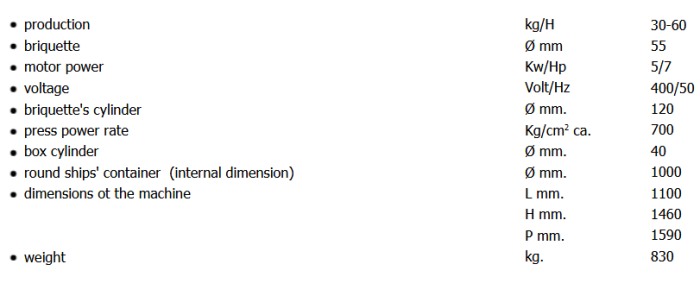

Dinamic - Model 70N -Briquetting Press

Hydraulic pressing machine intended for small carpentries and crafts environments to recycle wood chips and grinded chips with min.-max. 8-17% moisture content, transforming them into cylindrical briquettes of variable diameter (according to the press); they are obtained with no addition of alloying elements or chemical additives and considerably reducing the volume (1/5-1/10 according to the material). The briquetting press can be installed on silos or filtering units, on their internal or external side.

It works by a mechanic and hydraulic cycle of pressing at very high pressures. A hopper containing material is fixed to a loading plane made up of a rotating wheel feeding the material to a box, which is managed by a hydraulic cylinder. This latter has the function to pre-compress it in the compression chamber. A special compacting hydraulic cylinder presses then the material in the bush-pipe group.

- hydraulic vise in a strong and reliable steel monoblock without tie-rods connected to the extrusion pipe. It restrains the material moving inside the pipe. An apt gauge controls its working pressure.

- basement as oil tank (complete with oil level and thermostat for the oil temperature control) composed of a rectangular sturdy steel welded and powder coated frame;

- loading plane composed by a hopper for the material and a steel wheel mounted on its bottom to ensure the loading of the material in the box;

- IP55 electrical control board complete with an automatic timed cool-starter device. It lets the machine run also in very cold temperatures and with soft and progressive starting avoiding hard strokes and overpressures. It decreases the pressure on the vise during the first cycles;

- electric motor (IE2 high efficiency) connected to the hydraulic pump to have pressure in the circuit;

- hydraulic valve block without limit switches and electrovalves improving the production rates;

- box cylinder pre-compresses the material inside the compression chamber through the loading plane;

- compacting cylinder to enhance the production rate at the same installed power, equipped with a pressing punch to compress the material in the compacting opening;

- briquettes’ cylinder compresses the material in the sleeve-extrusion pipe group;

- hydraulic vice in a strong and reliable steel monoblock without tie-rods connected to the extrusion pipe, with the function of retaining the briquette during the compression phase and releasing it after reaching the specific pressure required for the formation of the briquette. A pressure gauge allows you to control the pressure of the vice;