- Home

- Companies

- Dinesh Tube ( India)

- Products

- Dinesh - Model SMO 254 - Flange

Dinesh - Model SMO 254 -Flange

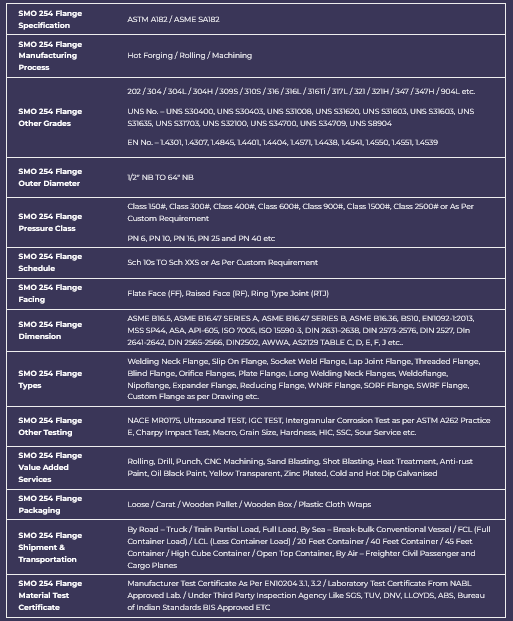

The Steel Exporter offers a wide array of 254 SMO Flanges, which are used in varied industrial and commercial sectors and is quality assured. SMO 254 Slip On Flanges (UNS S31254) are often used in Flue gas desulfurization scrubbers, Components used in petroleum production, Food processing equipment and more. In some applications, SMO 254 Spectacle Blind Flanges have been found to be a more cost effective substitute for high nickel and titanium alloys. SMO 254 Weld Neck Flanges are compatible with the common austenitic stainless steels.

SMO 254 Lap Joint Flanges are developed for use in halide – containing environments such as seawater, hydrochloric acid and contaminated sulphuric acid. Meanwhile, these SMO 254 Socket Weld Flanges are also being offered in different sizes and shapes to our customers. The chemical composition of SMO 254 Threaded Flanges typically has a slightly higher copper content than the AL-6XN alloy.

The original patent on SMO 254 Ring Joint Type Flanges was based, to some extent, on data that demonstrated that 0.5 % – 1 % copper in stainless steel produced an optimal combination of resistance to reducing acids and resistance to chlorides. SMO 254 Spacer Flanges contain copper only as a residual element, as do most austenitic stainless steels. The physical properties of SMO 254 Long Weld Neck Flanges are essentially equivalent as described herein. However, any differences in drop – evaporation tests for SMO 254 Nipo Flanges are not believed to be statistically significant.

A SMO 254 Flange is made from F44 super austenitic stainless steelscribed as a 6% Mo Flanges super austenitic stainless steel. The steel combines moderate mechanical strength (typically over 300 MPa yield strength) and high ductility with excellent corrosion resistance in seawater and a variety of industrial environments. Typically the alloy has a PREn(Pitting Resistance Equivalent) of 42-44 which ensures that the resistance to pitting corrosion is high. In addition, the steel provides good resistance to crevice corrosion.

A SMO 254 Flange is made from F44 super austenitic stainless steel attributes meaning that this high molybdenum stainless steel can be used successfully as an alternative to 300 series austenitic stainless steels (such as type 316) in applications where higher mechanical strength.

There is a need for enhanced resistance to pitting and crevice corrosion. It has a lower yield strength than duplex stainless steel (and much lower than super duplex steel) as well as pitting resistance comparable to super duplex stainless steel (such as UNS S32760 / S32750).

A Government of India approved Laboratory offers NACE 3.1 Certification, Mill Test Certificates, and ISO 17025 Standards for all Super Austenitic Stainless Steel (A182 F44 Material) Flanges. All raw materials procured by Oshwin Overseas are positively identified.

We manufacture and supply 6Mo Stainless Steel (UNS S31254) Flanges (ASTM A182 / ANSI B16.5) in a variety of sizes and pressure ratings to meet customer specific requirements. 254 SMO (A182 F44) Flanges are widely used in boiler manufacturing, brewing tanks, and desalination plants.

- SMO 254 Flange – Savoy Piping Inc., Make, Origin – India

- SMO 254 Flange – Ulma, Origin – Spain

- SMO 254 Flange – Matalfar, Origin – Italy

- SMO 254 Flange – Kofco, Origin – South Korea

- SMO 254 Flange – Melesi, Origin – Italy

- SMO 254 Flange – Viraj, Origin -India

- SMO 254 Flange – Galpetri, Origin – Italy

- SMO 254 Flange – Korea Flags, Origin – South Korea

- SMO 254 Flange – N.K Forge, Origin – Japan

- SMO 254 Flange – Ring Mill, Origin – Italy

- SMO 254 Flange – WMASS, Origin – India

- SMO 254 Flange – Korea Metal, Origin – South Korea

- SMO 254 Flange – Cladtek, Origin – South Korea

- SMO 254 Flange – CHW Forge Origin – India

- Oil and Gas Industries

- Food Processing Industries

- Equipments

- Pipeline

- Power Industries

- Ship Building Industries

- Paper Industries

- Cement Industries

- Chemical Industries

Buy SMO 254 Flange at an Attractive Discounted Price. Orders over USD $ 25000 qualify for a 2% discount. We offer free insurance and the best shipping rates.We offer free insurance and the best shipping rates. Our Prices are Always More Competitive and without any compromise in Quality of the Material.

SMO 254 Flanges Types- SMO 254 Welding Neck Flange

- SMO 254 Slip On Flange

- SMO 254 Socket Weld Flange

- SMO 254 Lap Joint Flange

- SMO 254 Threaded Flange

- SMO 254 Blind Flange

- SMO 254 Orifice Flanges

- SMO 254 Long Welding Neck Flanges

- SMO 254 Weldoflange

- SMO 254 Nipoflange

- SMO 254 Expander Flange

- SMO 254 Reducing Flange

- SMO 254 WNRF Flange

- SMO 254 SORF Flange

- SMO 254 SWRF Flange

- SMO 254 BLRF Flange

A SMO 254 flange is covered with plastic cloth and packed in a wooden box, a wooden pallet, and a wooden fumigated carro. With proper strips on wooden boxes, our packaging is fully waterproof and safe for transport.

SMO 254 Flanges Price List- 254 Flanges

US $0.5-1000 / Piece (FOB Price) - SMO 254 Pipe Flanges

US $300-500 / Ton (FOB Price) - SMO 254 Weld Neck Flanges

US $1-900 / Piece (FOB Price) - ASTM A182 254 smo plate flanges

US $0.5-1000 / Piece (FOB Price) - 254 Pipe Flanges

US $1-300 / Piece (FOB Price)

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

GIC provides a Manufacturer TC (Test Certificate) in accordance with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, and Third Party Inspection Report. In addition, we provide Standard certificates such as EN 10204 3.1 as well as additional requirements such as. NACE 01075. FERRITE CONTENT as per client request.

- EN 10204/3.1B,

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

- ASTM, ASME SMO 254 Flanges Value Added Services

Dinesh Tube India ensures that all materials are subjected to strict quality tests before being dispatched.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and MacroTest

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalised/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- Form A for the purposes of the Generalised System of Preferences (GSP)