- Home

- Companies

- RLC Technologies, Inc.

- Products

- RLC Technologies - Model 870 DTDU - ...

RLC Technologies - Model 870 DTDU -Direct Fired Thermal Desorption Unit

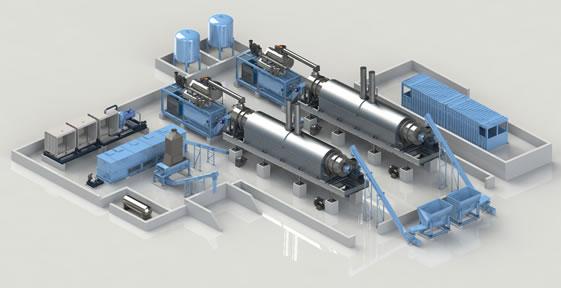

Drum Dimensions: 8 ft. Diameter x 70 ft. Length. Processing Capacity: 50 - 100 TPH, Stationary Facility.

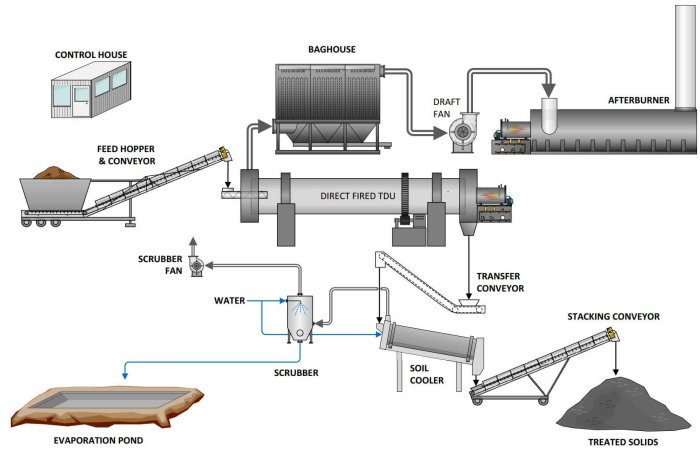

The direct fired thermal desorption unit contains three major components; a primary kiln for soil treatment, a bag house for dust removal, and an afterburner.

The direct fired thermal desorption unit contains three major components; a primary kiln for soil treatment, a bag house for dust removal, and an afterburner operating from 1600 deg. F to 2150 deg. F with a 2 second gas retention time to destroy the volatilized organics from the primary. The system is self contained and powered by an on-board generator that is capable of handling all energy requirements for the system. The generator and both primary and secondary burners are fired on No. 2 diesel fuel or No. 2 heating oil. They can, however, be converted to propane or natural gas if desired.

The treatment process is simple and begins with the feeding of the soils into a hopper at the rear of the unit. A controlled feed-rate for soil is achieved by the use of a variable speed conveyor that moves the soil directly from the hopper onto a slinger belt. The belt virtually throws the soils into the rotating kiln drum. Once in the hopper, soil is moved down the kiln by gravity. A specially designed flighting system in the drum causes the soils to be dropped directly into the center of the main burner flame. The flame, positioned at the low side of the drum, provides the heat that is absorbed by the soil. This heat causes the volatile compounds to be released into the air stream and carried out of the kiln. The kiln temperatures can be controlled for the optimum efficiency of desorption, based upon contaminate concentration and soil type.

The air stream, laden with water and organic vapors and dust particles, exits the drum directly into the bag house. The dust is removed from the air stream to meet all standards for particulate emissions from the exhaust stack. The resulting air flow, carrying the vapors, is moved directly to an afterburner. The vapor-laden air passes through the afterburner at which point the organics are destroyed. The soils exit the kiln at temperatures of 600 deg. F to 900 deg. F. At the point of discharge, the soil is re-hydrated to suppress fugitive dust emissions.

Operation of the unit is performed primarily from the main control station. From here, the operator is able to start, operate, and shut the unit down. Process instrumentation process variables are displayed here, providing current information regarding all system parameters.

The innovative design and function of our Anaerobic Thermal Desorption Units provide benefits for oil and gas job sites around the globe.

There are several benefits to our process, including environmentally friendly nature, waste minimization, large treatment capability, and year-round operation.

Environmentally Friendly Nature

Our technology eliminates the need for land disposal or incineration, exceeding the most stringent clean-up criteria. The closed system design reduces atmospheric emissions to a fraction of that of direct fired systems. Hydrocarbons are separated and recovered, not burned and released into the atmosphere as greenhouse gases.

Waste Minimization / Recycling

The non-destructive nature of the process allows wastes to be converted into useful products. Our technology can produce a commercially valuable product while reducing and de-listing a hazardous waste stream.

Large Treatment Capability

Any compound, organic or inorganic, that can be converted to a higher volatile substance at our system’s boiling point can be removed from a stable matrix and further recycled.

24-Hour Year-Round Operation

Our plants are designed to operate about 90% of the time within a 24-hour, year-round schedule.

RLC Technologies has built and delivered over 30 indirect fired thermal desorption plants to job sites around the world. With a focus on safety and a sophisticated design and control system, our thermal desorption plants have proven to be safe and reliable time and time again.

Custom Design

Our plants are custom-designed for each specific application, depending on the customer’s specific needs and type of contaminated material. Each one of the ATDU plants we build are constantly improving in design and performance to provide the very best for our customers.

Low Maintenance Design

Our custom design enables our equipment to operate successfully with minimum required maintenance. Abrasive materials, like those found in drill cuttings and other wastes, do not cause wear from friction as they do in other thermal treatment systems.

Mobility / Emergency Response

Our plants can be easily placed on trailers and transported to remote sites. Quick electrical disconnects allow easy mobilization and demobilization.

Worldwide on-Site Assistance

We want our clients to be able to operate properly and effectively. Therefore, our experienced specialists provide on-site training and worldwide assistance during the plant set-up and all operations thereafter. We are ready to provide our clients with spare parts, technical data, and consultations as needed.

RLC Technologies offers competitive pricing, a full-year warranty, and suitable payment terms to meet the needs of our clients all across the world.

Competitive Price

We structure our business so we can offer our clients internationally competitive prices.

Cost Effectiveness

We help our clients operate in the most cost-effective way by transforming waste into a product that has commercial value, low-maintenance design, high-quality components, stable and reliable operations, and mobility.

De-Listing of Waste While Recovering Oil

D, F & K wastes can be processed through our ATDU and meet UTS, allowing for disposal in a non-hazardous or industrial landfill.

One Year Full Warranty

We offer One (1) year warranties on all of our equipment.

Suitable Payment Terms

We are open to using different INCOTERMS terms when pricing our equipment. We are also willing to discuss different payment terms with our clients. All transactions are facilitated via Ex-Im financing for international sales.

Our equipment is completed with a state-of-the-art reliable control and safety system which assures stable operations and virtually eliminates the risk of accidents.

RLC Technologies ATDU systems have been operating safely for more then twenty years. Our FM/NFPA compliant combustion system have been certified by CE/ATEX and as well as Safety Integral Level 2 (SIL 2). CE/ATEX and/or SIL certification are available with any of our ATDU products. Our TDU facilities are also designed per NEC Class 1 Division 1 or 2 and/or ATEX or IEC Zone 1 or 2 or IEC explosion proof for safe operation in Hazardous Area locations. In addition to certifications, the ATDU control system is designed with multiple redundant interlocks to ensure safe operation.

We help our clients have more productive uptime with less maintenance or stalled work due to repairs. Unlike most competing technologies, we guarantee a 90+% uptime.

With a high throughput at a low operating cost, clients are able to operate their job sites properly and efficiently.

Our systems are built to be expanded or added onto depending on production needs. Since the system’s components are modular, they can easily be enlarged as your operations expand.

Due to the modular nature of our TDU equipment, existing systems can be expanded to increase processing capacity as demand increases. Further to this cost savings can be realized as there are many common components which can be shared between systems. Furthermore, a smaller ATDU system can easily be upgraded to a unit with a higher production capacity.