- Home

- Companies

- Ozone Research and Applications India ...

- Products

- Ozone - Disc Filters for Effluent ...

Ozone - Disc Filters for Effluent Treatment Plants (ETP)

ORAIPL manufactures and installs Disc Filters for Effluent Treatment Plants, and other water treatment systems. Our Disc Filters are engineered to deliver unmatched filtration efficiency, continuous operation, and exceptional cost savings for modern wastewater treatment systems. Designed specifically for industrial effluent treatment applications, these advanced filters effectively remove fine suspended solids and reduce BOD (Biochemical Oxygen Demand)—ensuring cleaner, reusable water and regulatory compliance for your facility.

How ORAIPL Disc Filters Work

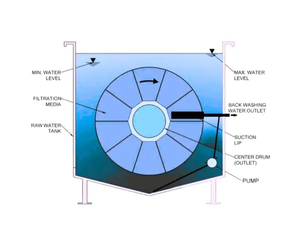

The ORAIPL Disc Filter operates on a simple yet highly efficient principle of outside-to-inside filtration combined with automatic backwashing for uninterrupted performance.

- Filtration Phase

Wastewater flows from the outer surface of a stack of fiber-media discs mounted on a central shaft. Each disc is separated by spacers to allow uniform flow through the filter media.

As the water passes through the fine fiber cloth, suspended solids are trapped on the outer surface, while the clean filtrate collects in the central drum and exits through the outlet. - Automatic Cleaning (Backwash) Phase

Over time, as solids accumulate, the water level inside the tank rises. This triggers the level sensor, activating both the disc rotation mechanism and backwash suction system.

During this stage, powerful vacuum nozzles draw out trapped impurities, transferring them to the sludge management system.

The process is continuous—while one section of the discs is being cleaned, the remaining discs continue filtration—maintaining steady flow and efficiency. - Cycle Repetition

Once cleaning is complete and the water level drops back to normal, the system automatically resumes its filtration cycle—ensuring 24×7 operation with minimal human intervention.

With a legacy of innovation in water treatment technology, ORAIPL delivers disc filtration systems that combine robust construction, intelligent automation, and engineering precision.

Each system is built to withstand demanding industrial environments, offering:

- Long service life with corrosion-resistant SS304 / SS316 / FRP construction

- Smart automation with level probes and suction pumps

- Continuous filtration without any process interruption

- Easy integration with existing ETP/STP infrastructure

ORAIPL Disc Filters embody simplicity, reliability, and sustainability—helping industries achieve cleaner water and greener operations.

- Investing in ORAIPL Disc Filters means investing in efficiency, reliability, and sustainability.

- Whether it’s improving effluent quality, meeting environmental standards, or optimizing plant operations—ORAIPL provides the technology and expertise to make your water management smarter and future-ready.

Parameter - Specification

- Filtration Type: Outside-in through fiber media cloth

- Filtration Rating: Up to 10 µm (customizable)

- Capacity: 50 MLD to 150 MLD

- Flow Capacity: Modular systems – scalable from 10 m³/hr to 500 m³/hr or higher

- Media Material: Polyester / Fiber filter cloth

- Body Construction: SS304 / SS316 / FRP

- Cleaning Method: Automatic backwash with suction nozzles

- Operation Mode: Continuous filtration and cleaning cycle

- Control System: Level-sensor or PLC-based automation

- Power Requirement: Low – optimized for energy efficiency

- Industrial Effluent Treatment Plants (ETPs)

- Sewage Treatment Plants (STPs)

- Suspended Solids and BOD Removal Systems

- Water Recovery and Recycling Units

- Pre-filtration for Membrane Systems (UF / RO)

- Upgrading or Retrofitting Existing Filtration Systems