- Home

- Companies

- RK2 Systems, Inc.

- Products

- Corona - Model RK-2G - Discharge Ozone ...

Corona - Model RK-2G -Discharge Ozone Generators

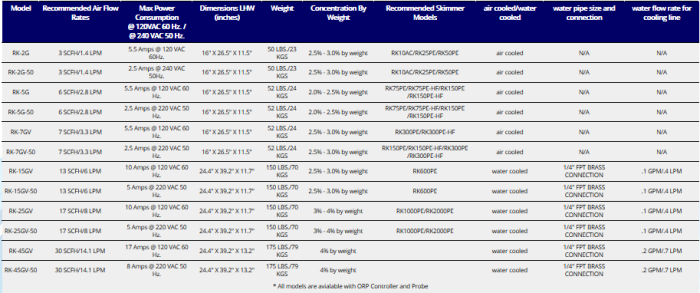

RK2 Systems models RK-2G through RK-45G produce ozone at 2, 5, 7, 15, 25, 45grams/hour at 3-5% by weight. All systems operate under vacuum, for safety, efficiency and ease of operation. Each model has configurable feed-gas options (integrated oxygen concentrator system is standard), multiple safety features, self-diagnostic switching and robust construction. Variable ozone output control is available on models RK5G through RK-45G.

Ozone is the most powerful oxidizer and disinfectant that can safely be used in multiple industrial and commercial applications. It destroys all organic molecules, renders dissolved metals insoluble and oxidizes inorganic contaminants. With a relative sanitizing strength of 1 PPM aqueous ozone to 200 PPM chlorine, ozone is safe for all surfaces (excluding natural latex rubber).

Ozone is an EPA approved antimicrobial and listed as safe for discharge into surface and groundwater; FDA approved as an antimicrobial food additive, and USDA approved as an antimicrobial organic food additive. Leaving no measurable residual (no rinse), RK2 Systems Corona Discharge series provide a non-corrosive solution for continuous or on-demand sanitation. Each of our units are built to UL standards, are NSF validated for antimicrobial efficacy and safety and are designed as totally integrated systems providing a synergistic approach to water or surface sanitation in multiple commercial and industrial applications while giving facility operators a simple, automated, low maintenance system.

All Corona Discharge Series units offer the following:

- Integrated Safety Management System

- Oxygen flow meter

- Complete ozone isolation during shut-down

- Automatic feed-gas flow control to maintain

- proper operational set-points

- Dry Contacts for remote ambient ozone monitor

- shut-down and user interlock

- Powder-coated steel enclosure designed to NEMA-12 specifications

- 20 kHz ceramic tube corona discharge ozone cells

- Fault protection for:

- Door open

- Feed gas pressure failure

- Vacuum loss

- Overheating

- Water backflow

- Current overdraw

- Over-pressurizing of oxygen concentrator cells

How Ozone and Protein Fractionation Works Together

Ozone Injection enhances the fractionation process in a number of ways. Ozone oxidizes various pathogens, from bacteria to viruses. Ozone is extremely effective on organic water tints creating crystal clear water. Ozone also breaks down the structure of larger organic molecules, which facilitates their removal by fractionation. Being a three-part oxygen molecule, ozone dramatically increases oxygen concentration. Ozone in doses appropriate for aquaculture is very safe.

The fractionation and ozone combination is extremely effective in a variety of applications. Grow out tanks and aquaria displays with heavy bio-loads become remarkably cleaner. Clean Systems, such as larval rearing or holding tanks can become crystal clear. Protein fractionation with ozone is excellent for systems with heavy mucous concentrations such as closed or semi open finfish and shellfish holding systems. Other applications include purging systems, grow out systems, effluent treatment as well as influent water treatment for use within partial and full flow thru systems.

The protein fractionation process increases water clarity and oxygen concentration, and also destroys and removes pathogens. Consequently, appetite, stocking densities, feed and growth rates are all enhanced and animal health improved.

Used within aquaculture, live seafood holding as well as most public aquariums worldwide, protein fractionators are an essential component within any aquatic life support filtration system. Protein fractionation is effective in seawater, freshwater as well as brackish water systems, within partial or full flow applications. Individual models are available with processing flow rates from 3 to 2000 gallons per minute. For larger flow rate applications, our protein fractionators can be incorporated into any modular system design, thus allowing us to process any system volume where protein fractionation is required.