- Home

- Companies

- AXD Service Industries Corporation ...

- Products

- DLNG - Blowers & Exhausters, Skid ...

DLNG - Blowers & Exhausters, Skid Fabrication Systems

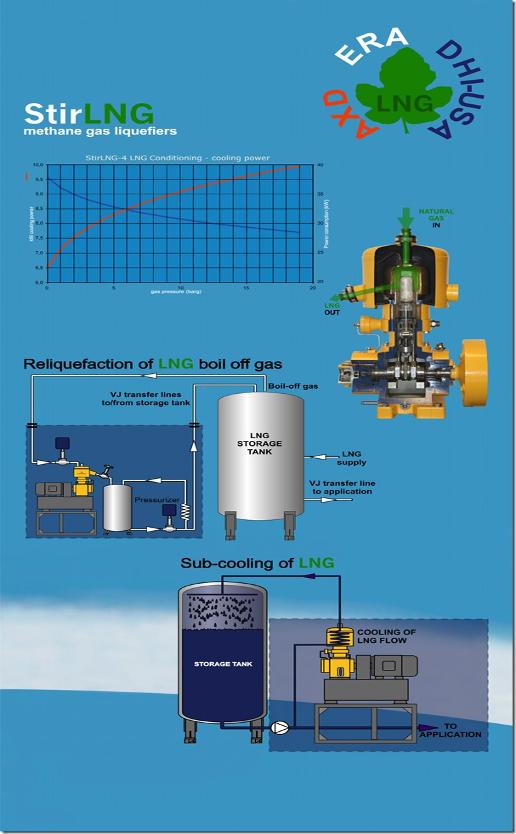

The Liquid Power Cooler - Re Liquefier (LPC-RL) is the solution for applications in which the design of a system allows: sufficient cooling by natural flow, and the boil-off gas developed by the application will collect easily at the top of the application cryostat.

Blowers & Exhausters, Skid Fabrication, DLNGtm Systems LNG small scale production & conditioning systems Marine, Bunker, Barge, LNG!

- Marine onboard LNG fuel chilling, no BOG!

- Stirling Power Cooler LPC-RL Reliquefaction of boiling gases.

- AXD-ERA: “Official Supplier of Stirling Cryo for LNG markets USA!” 732-946-9462.

- Applications Include: Truck fuel centers, Ferry fuel bunker, Small scale LNG stations.

The liquid cryogen (neon, nitrogen, argon, methane, etc.) inside the application cryostat or storage vessel evaporates as a result of the energy given off by the application. The boil-off gas that is formed collects at the top of the cryostat. The gas is fed through a vacuum jacketed (VJ) line to the Stirling cryogenerator where it is re-liquefied. It then flows back to the application cryostat through another VJ line.

The temperature of the cryogenerator cold head is monitored continuously. If the temperature starts to drop, the capacity of the cryogenerator is reduced and vice versa. This compensates for the variation in the heat load from the application. A small regulated heater is incorporated at the cold head to prevent the liquid from freezing. The LPC-RL is fully automatic. When operating normally, it does not require any operator attention.