Kadant - Doctor & Roll Cleaning Blades

Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup. With thousands of installations around the globe, Kadant doctoring and roll cleaning technology offer high-performance cleaning and water removal in a variety of roll cleaning and scraping applications.

Fluid flows from the receiving chamber (A) through the inlet check valve (B) into the pump tank (C). The 3-way valve (D) is open between the pump tank and the receiving chamber, equalizing the pressure between them through the equalizing line (E).

When the level control (F) senses that the pump tank is full, the 3-way valve energizes to admit the motive pressure into the pump tank (C). The motive pressure forces the fluid past the discharge check valve (H) and out the discharge line.

Once the level control (F) senses the pump tank has emptied, the 3-way valve (D) de-energizes, shutting off the motive pressure, and opening the vent port in the valve. This allows the pump tank (C) and the receiving chamber (A) to equalize in pressure. The cycle will now repeat.

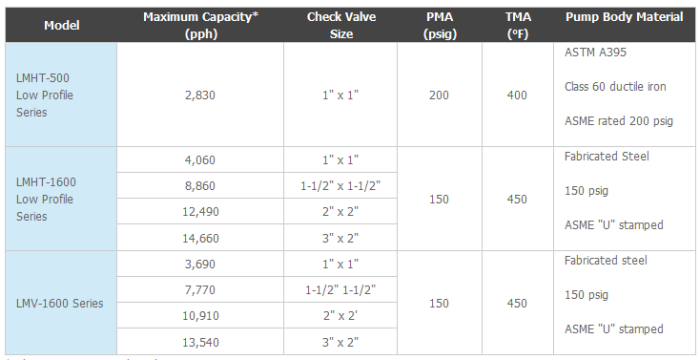

Above Capacities are based on:

- Single pump tank

- Steam as motive pumping pressure

- Maximum fill head

- Motive pressure being 20 psig higher than static back pressure

- 210°F condensate temperature