- Home

- Companies

- Henan Doing Mechanical Equipment Co., ...

- Products

- DOING - Model DY - Petroleum oil sludge ...

DOING - Model DY -Petroleum oil sludge recycling pyrolysis machine

Petroleum oil sludge has increased during petroleum oil exploration engineering as our demand for petroleum oil is getting larger, so does the pollution it brings to our land. If you want to dispose of it, an oil sludge recycling pyrolysismachine may help you a lot. You can also invest in this plant to make money from the end products.

1. Waste Oil Sludge Pyrolysis Process

The main technology we used to dispose of the oily sludge is pyrolysis. Let’s see the specific process of working:

①Collect all of the oil sludge together and then unload them to the workshop. Most of our oily sludge recycling pyrolysis plants are installed in the open air. And then use our auto screw feeder to feed them into the pyrolysis furnace.

②Under an oxygen-free, high temperature and sealed environment, the three main components of oil sludge, oil, sludge, and water, will be decomposed.

③When the temperature rises to a certain degree, oil gas will come out. Among them, heavy particles in the gas will be liquefied into heavy oil and then dropped into the heavy oil tank; light particles in the gas will rise up and liquefied into light oil in the horizontal tube condenser and then also be reserved in the oil tank.

④The slag will be automatically collected during the process.

The flue gas, before safe emission, may contain carbon and cause global warming, so they need to be cooled down at first and then go through de-dusting, washing, water spray, ceramic ring adsorption and activated carbon adsorption to remove the harmful matters in it. Finally, it will be discharged safely.

Note: we strongly recommend you choose the continuous pyrolysis machine if you have big quantities of oil sludge to dispose of, because it's more efficient and it can acheive 24/7 hours running.

Henan Doing Company promises that all the flue gas discharging has met the EU environmental protection and emission standards. Since there will be combustible gas and flue gas generated during the workflow of our oily sludge treatment system, we have specific ways to deal with them. In the hydra seal, the combustible gas will be desulfurated and cleaned and then reused as fuel to heat the pyrolysis reactor.

1. Advantages/Superiority of DOING Petroleum Oil Sludge Recycling Pyrolysis Machine

l Original Designs

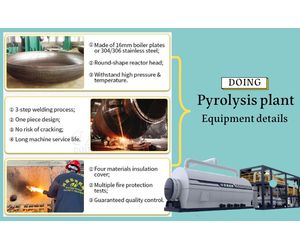

Four layers of refractory materials are added in the casing of the pyrolysis reactor to improve heat utilization and prolong the life-span of the reactor. The new heating structure combines wind-type heating and direct heating together.

l Multiple Uses For Convert Waste to Energy

The pyrolysis technology cannot only be used in oil sludge treatment, but also in recycling tire and plastic to oil pyrolysis machine.

l Energy Saving

High working efficiency helps you to reduce unnecessary costs.

Combustible gas can be used as fuel to heat the reactor

l Safety Operation

We use 100% avoid-burn technology and 100% explosion-proof technology. The professional thermometer and pressure gauge can inspect the temperature and air pressure at any time.

l We use the outlet valve clog-proof technique.

Bilayer explosion-proof valve: located in pyrolysis reactor maintenance/inlet door, equipped with double-layer of aluminum sheets.

3. How to Choose a High-Quality Petroleum Oil Sludge Recycling Pyrolysis Machine?

If you decide to buy a high-quality oil sludge treatment plant, you will consider the materials, production techniques, and durability. In DOING, we use auto-welding techniques during our production process to make sure of the quality. We also have a professional research team which has done thousands of experiments to try new oil sludge treatment methods and upgrade the techniques of the plant to prolong the life-span of the plant.

4. Best Choice for the Oil Sludge Treatment and Disposal Companies

This kind of crude petroleum oil sludge recycling pyrolysis machine is the best choice for most of the oil sludge treatment and disposal companies. It reduces the pollution coming from the crude oil sludge and turns it into useful materials. At the same time, the machine is environmental-friendly. The emission of this plant meets the EU environmental protection emission standard. Besides, due to the energy-saving design, the plant has low fuel consumption. Depending on the eco value and the market value, this plant will have a bright future.

So far, Henan Doing Company is one of the minorities which uses pyrolysis technology maturely and safely in the waste recycling industry. Meanwhile, as one of best, DOING devotes a lot to oil sludge recycling in the oil field. Almost all the primary oil fields in China have been benefited by our petroleum oil sludge recycling pyrolysis machine. If you are interested in it, you can leave your message to us now.

Whatsapp/Tel: +86 13526692320

E-mail: oilmachine@wastetireoil.com

Official Web: Professional Waste Tire Plastic Oil Sluge Pyrolysis Plant For Sale Manufacturer