ISVE S.p.A.

- Home

- Companies

- ISVE S.p.A.

- Products

- ISVE Recycling - Model B-70/80S - ...

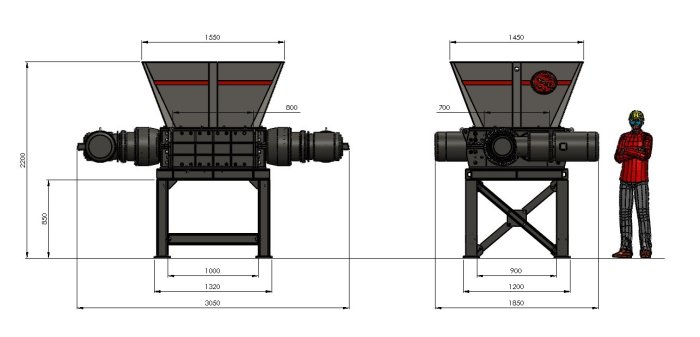

ISVE Recycling - Model B-70/80S -Double-shafts Shredder

FromISVE S.p.A.

Main Features: Cutting chamber: 850X750 mm. Installed horsepower: 15 KW + 15 KW. Drive: gears through oil bath reduction gear. Cutter shafts: 2. Hardened cutters: 20. cutters diameter: 430 mm. Thickness diameter: 40 mm. Spacing combs: 20. Average cutter revs./min.: 16. Production: 1-1,5 t/h. Safety precautions: emergency stop, reversal system in case of overloading. Manufactured to EC standards.

Do you want to learn more about? Please, write us at headoffice@isve.comMost popular related searches

double shaft shredder

shredder

emergency stop

roller bearing

cutter shaft

sealing system

belt conveyor

protective equipment

packaging film

- interchangeable hopper;

- loading and unloading conveyor belts

- custom basement;

Multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working.

Recommended for shredding pieces of wood, rags, plastic blocs leather, small tyres, paper, cardboard, packaging, polyethylene banding, plastic film, etc.

- Strongwelded sheet framework mounted on anti-vibrating feet;

- Support for barrel roller bearings with sealing system against dust and liquids;

- High thickness shafts with 20 special anti-wear steel cutters and 20 spacers to facilitate unloading of shredded material:

- New graduated arrangement of cutter teeth for better taking and cut progress;

- N.2 epicyclic reduction gears with rotation axes parallel to the cutter axis;

- N. 2 motors of 15 KW for a total of 30 KW;

- Transmission system in oil bath with steel gears and pinions ;

- 850×750 mm. cutting chamber;

- Hopper in bolted sheet metal for loading from the top;

- Basement made in steel tubular equipped with protection nets or arranged for the conveyor belt.

- Weight: 4.700 kg.

- Electrical board built according to CEE rules and provided with power limiting device inverting cutters motion in case the working charge of the machine is higher than the programmed value;

- Main internal card for the control of all system peripherals devices;

- Emergency control functions for stopping the plant in the case of accidental introduction of ferrous material.

- Made to CE standards.