- Home

- Companies

- Douglas Manufacturing Co., Inc.

- Products

- Douglas - Durable Drum Pulleys

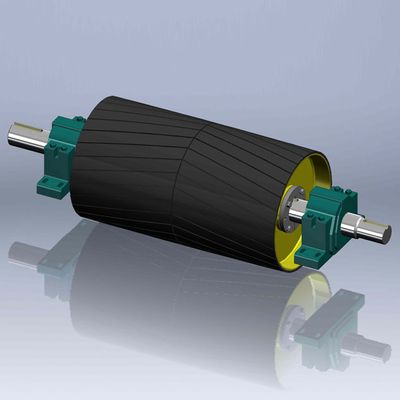

Douglas - Durable Drum Pulleys

Douglas Manufacturing Co., Inc. engineers drum pulleys that are among the most durable in the industry. With over four decades of experience and the utilization of advanced computer design and analysis tools, Douglas ensures high-quality construction. Each drum pulley features a single piece rolled rim made from solid steel pipe or tubing, promoting longevity, durability, and proper belt tracking. The welded one-piece solid steel rims and end discs maximize strength. Rubber lagging applied using a state-of-the-art autoclave system ensures superior bond and quality control. These pulleys come in five classes to meet various needs and include XT Style hubs and bushings, Keyless Locking Elements, and stainless steel options.Drum pulleys are engineered by the professionals at Douglas to be the most durable pulleys in industry. They are developed using a combination of more than 40 years of experience and state of the art computer design and analysis tools.

All Douglas drum pulleys feature our exclusive single piece rolled rim, solid steel pipe or tubing design that ensures long-life, durability and helps ensure proper belt tracking.

One piece solid steel rims and end discs are welded into a single assembly using the most precise welding methods available to ensure the maximum level of strength and durability.

Rubber lagging is applied in our plant using a state of the art autoclave for maximum bond and total quality control.

- Heavy Duty

- Mine Duty

- Pulp and Paper Mill Duty™

- Quarry Duty

- True Engineered Class

XT Style hubs and bushings are standard with Keyless Locking Elements and Stainless steel hubs and bushings. Lagging styles include:

- Standard Lagging in plain, herringbone/chevron, diamond, spiral or with machined finishes

- Ceramic Lagging for increased lagging life and more traction

- Replaceable Rim Lagging®