- Home

- Companies

- Dover Motion

- Products

- Dover Motion - Model DMCM - High ...

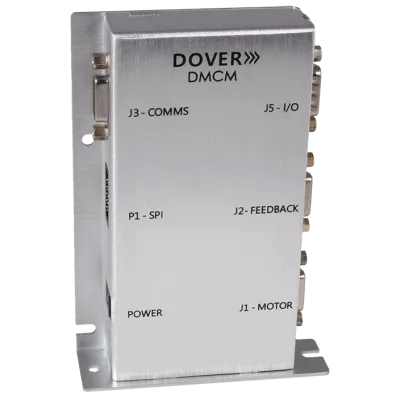

Dover Motion - Model DMCM -High Performance Motion Control Module with Integrated Drive

The Dover Motion Control Module (DMCM) serves as a sophisticated controller and drive system designed to optimize the performance of stepper and servo motors. It supports 3 phase servo, 1 phase servo, and 4 wire stepper motors, delivering variable current outputs for precise control. Featuring advanced interpolation, it is compatible with both analog and digital encoders. This module is distinguished by its unique motor current scaling feature, allowing for precise current resolution which enhances stability and closed-loop control. Integrating a single power source for motor and logic, the DMCM ensures operational efficiency with features like disconnecting motor power while maintaining logical operations. The module includes high-speed trigger capabilities, enabling devices like lasers or cameras to be activated at exact stage positions. Communication is seamless through RS-485, CAN, or SPI interfaces, making it well-suited for multi-axis applications. The DMCM's technical prowess makes it ideal for both open and closed-loop configurations.

The Dover Motion Control Module (DMCM) provides versatile high performance motion control with a built in drive that is capable of running 3 phase servo, 1 phase servo, or 4 wire stepper motors at various current output levels. It includes interpolation for use with either analog or digital encoders.

Design Features

The DMCM – Dover Motion Control Module is a versatile controller and servo drive capable of powering stepper or servo motors and provides many advanced capabilities. It is the only drive in its class that allows selectable motor current scaling to ensure optimal current resolution for optimal stability and closed loop control performance. A single power source is used for both motor and logic supply, with on board intelligence that allows the motor power to be disconnected while leaving the logic powered on.

A high speed Trigger On Position can be configured to allow a laser or camera to be triggered using the exact position of the stage. This can be setup as a constant incremental trigger at a fixed distance, or can be configured using a stage position look up table to trigger at different intervals.

The DMCM also includes an interpolated encoder feedback digital quadrature output. This signal can also be used as a master signal sent to a slave axis for coordinated motion.

Fast multi-axis communication can be implemented using RS-485, CAN or SPI. RS-485 is also available for multi-axis applications.

- Multiple communication options: RS-232, RS-485, CAN, and SPI

- 2 Digital Inputs, general purpose or used for step/direction motion command

- 2 Digital Outputs

- 1 Analog 12 bit, 0-10V Input

- Accepts Analog or digital differential encoder feedback inputs

- Positive and Negative Limit, Index, and Home inputs

- Digital Position Feedback Output

- High Speed Trigger on Position Output

- 24 – 48V power input

Options

Accessory Cables available for:

- Power supply connection

- Motor

- Encoder

- Communications (USB, RS232, RS485, CAN, or SPI)

For open loop stepper, closed loop stepper, servo, and multi-axis applications

- Multi-axis co-ordinated motion capabilities

- Encoder Position Output Compare signal for syncing laser pulses or camera image capture

- Can be integrated into a control box (board only)

- For benchtop use, orderable as a single axis module with enclosure and mounting features