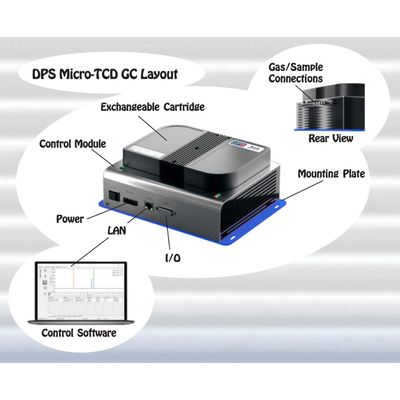

The DPS Micro-TCD Gas Chromatography System is a compact and versatile apparatus designed to efficiently perform analytical chemistry tasks with its advanced thermal conductivity detectors. The system houses 1 to 4 channels, each with its independent GC oven, analytical column, pre-column, and dual micro-machined TCD detectors. This allows for flexibility in complex analyses that can be executed rapidly. The system features integrated components such as injection and backflush valves for automation, a built-in stream selector, and on-board chromatography software. Designed for continual operation, it supports fast analysis timeframes and minimal maintenance. Communication capabilities include RS232, RS485, and Ethernet with Modbus and TCP protocols, enhanced by a memory storage capacity of up to 256Gb. Its small, robust design is suitable for online, at-line, or laboratory environments, providing essential temperature and pressure control with precision down to 0.001 degrees or kPa. Suitable carriers include helium, argon, nitrogen, or hydrogen.